Ford Fiesta: Climate Control System - General Information / Refrigerant Identification Testing. General Procedures

Special Tool(s) / General Equipment

| Refrigerant Identification Equipment |

Activation

-

NOTE: Use Refrigerant Identification Equipment to identify gas samples taken directly from the refrigeration system or storage containers prior to recovering or charging the refrigerant system.

NOTE: Use Refrigerant Identification Equipment that conforms to SAE J1771 for R-134a or SAE J2912 standard identifies R-134a and R-1234yf.

Follow the instructions included with Refrigerant Identification Equipment to obtain the sample for testing.

-

198‐RI2012yfp A/C Refrigerant Analyzer for use with R134a and R1234yf vehicles

Use the General Equipment: Refrigerant Identification Equipment

-

198‐RI2012yfp A/C Refrigerant Analyzer for use with R134a and R1234yf vehicles

-

NOTE: The refrigerant identifier displays one of the following:

-

If the purity level of R-134a is 98% or greater by weight, the green

PASS LED . The weight concentrations of R-134a, R-12, R-22, hydrocarbons

and air will be displayed on the digital display.

-

If refrigerant R-134a does not meet the 98% purity level, the red FAIL LED

and an alarm sounds alerting the user of potential hazards. The weight

concentrations of R-134a, R-12, R-22 and hydrocarbons are displayed on

the digital display.

-

If hydrocarbon concentrations are 2% or greater by weight, the red FAIL LED

, "Hydrocarbon High" will be displayed on the digital display, and an

alarm sounds alerting the user of potential hazards. The weight

concentrations of R-134a, R-12, R-22 and hydrocarbons also are displayed

on the digital display.

-

If the purity level of R-134a is 98% or greater by weight, the green

PASS LED . The weight concentrations of R-134a, R-12, R-22, hydrocarbons

and air will be displayed on the digital display.

-

The percentage of air contained in the sample is

displayed if the R-134a content is 98% or greater. The refrigerant

identifier eliminates the effect of air when determining the refrigerant

sample content because air is not considered a contaminant, although

air can affect A/C system

performance. When the refrigerant identifier has determined that a

refrigerant source is pure (R-134a is 98% or greater by weight) and air

concentration levels are 2% or greater by weight, it prompts the user if

an air purge is desired.

-

If contaminated refrigerant is detected, repeat the

refrigerant identification test to verify the refrigerant is indeed

contaminated.

-

NOTICE: If contaminated refrigerant is detected, DO NOT recover the refrigerant into R-134a recovery/recycling equipment. Recovery of contaminated refrigerant contaminates the recovered refrigerant supply and may damage the recovery/recycling equipment.

NOTE: Install a new suction accumulator, receiver drier or receiver drier element as directed by the A/C system flushing procedure.

Recover the contaminated refrigerant using suitable recovery-only equipment designed for capturing and storing contaminated refrigerant only.

-

Determine and correct the cause of the customer's initial concern.

-

Refer to Air Conditioning (A/C) System Flushing procedure in Group 412.

-

Dispose of the contaminated refrigerant in accordance with all federal, state and local regulations.

Heater Core Leak Check. General Procedures

Heater Core Leak Check. General Procedures

Inspection

NOTE:

A coolant leak in the heater hose could follow the

heater core tube to the heater core and appear as a leak in the heater

core...

Refrigerant Oil Adding. General Procedures

Refrigerant Oil Adding. General Procedures

Special Tool(s) /

General Equipment

Air Conditioning Service Unit

Refrigerant Oil Injector Set

Filling

Adjust the oil injector piston and fill the oil

injector with the correct amount of clean, new Motorcraft® PAG

Refrigerant Compressor Oil (YN-12-D)...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Perimeter Anti-Theft Alarm - Overview. Description and Operation

Overview The perimeter alarm system deters unauthorized entry into the vehicle by sounding the horn and flashing all the turn signals. When an unauthorized entry occurs, the horn and the turn lamps activate. The panic alarm operates similar to the perimeter alarm, but only activates using the panic button on the RKE transmitter...

Ford Fiesta 2014 - 2019 Service Manual: Rear Lamp Assembly. Removal and Installation

Removal 4-Door sedan rear outer lamp assembly NOTE: LH shown, RH similar. Remove the push pin retainer. Position aside the RH or LH luggage compartment side trim panel. Disconnect the rear lamp assembly electrical connector...

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Camshafts. Removal and Installation

- Engine Component View. Description and Operation

- Maintenance Schedules

- Timing Belt. Removal and Installation

- Engine System - General Information

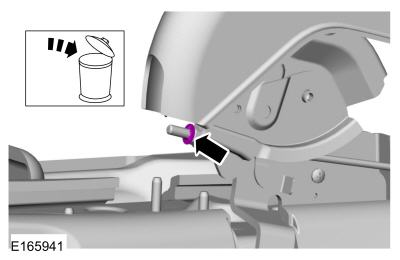

Parking Brake Control. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the floor console.Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Remove the driver seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Remove the parking brake cable adjustment lock nut.

Loosen the parking brake cable adjustment nut.

Loosen the parking brake cable adjustment nut.