Ford Fiesta: Engine - 1.6L EcoBoost (132kW/180PS) – Sigma / Oil Pump. Removal and Installation

Special Tool(s) / General Equipment

|

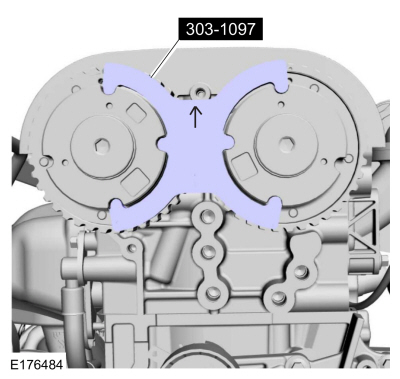

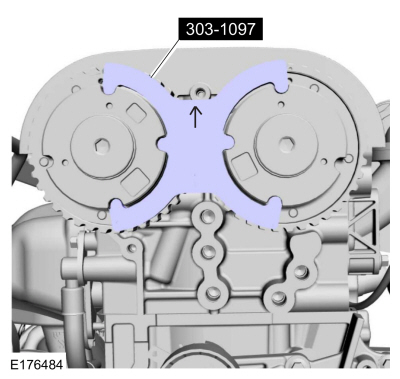

303-1097 Locking Tool, Variable Camshaft Timing Oil Control Unit TKIT-2010B-FLM TKIT-2010B-ROW |

| Trolley Jack | |

| Wooden Block | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Metal Brake Parts Cleaner PM-4-A, PM-4-B, APM-4-C |

- |

Removal

-

Remove the crankshaft front seal.

Refer to: Crankshaft Front Seal (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

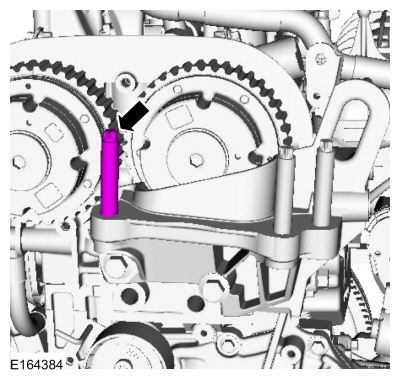

- Remove Special Service Tool: 303-1097 Locking Tool, Variable Camshaft Timing Oil Control Unit.

|

-

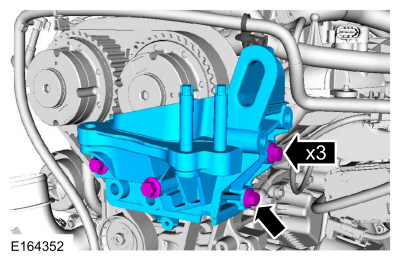

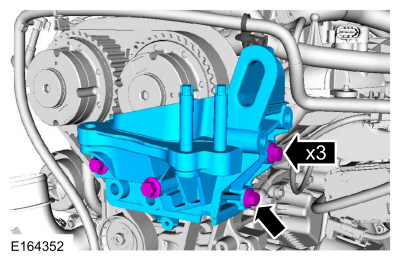

NOTE: There are different length of bolts noted in removal.

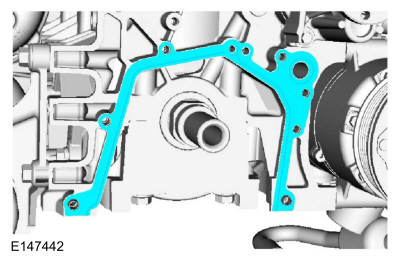

NOTE: Install engine mount bracket to support the engine during oil pan removal.

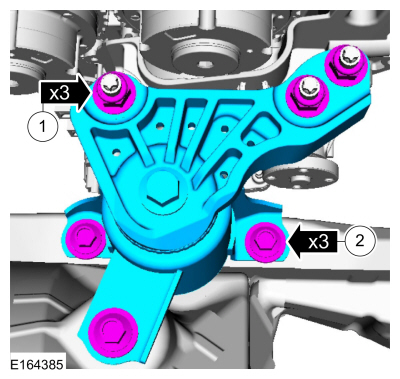

Install the engine mount bracket and the bolts.

Torque: 41 lb.ft (55 Nm)

|

-

Install the engine mount stud.

Torque: 89 lb.in (10 Nm)

|

-

NOTE: Install engine mount to support the engine during oil pan removal.

-

Install the engine mount and the nuts.

Torque: 59 lb.ft (80 Nm)

-

Install the bolts.

Torque: 35 lb.ft (48 Nm)

-

Install the engine mount and the nuts.

|

-

Remove the oil pan.

Refer to: Oil Pan (303-01A Engine - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Removal and Installation).

-

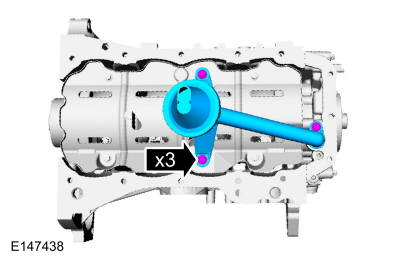

Remove the bolts and the oil pump screen and pickup tube.

|

-

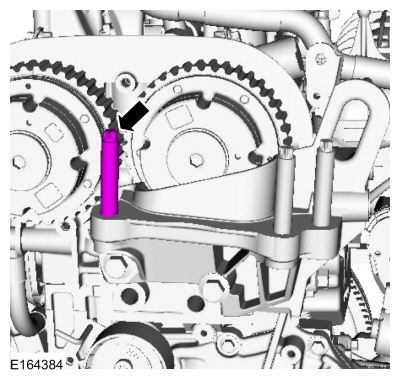

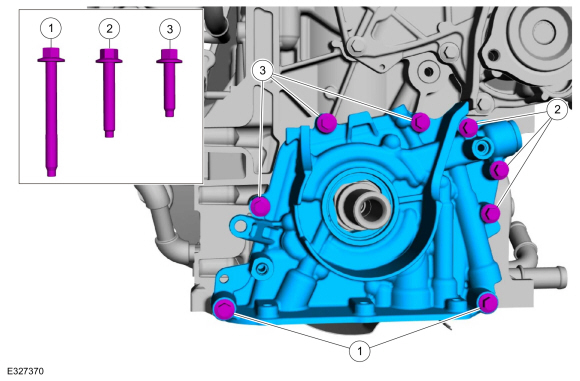

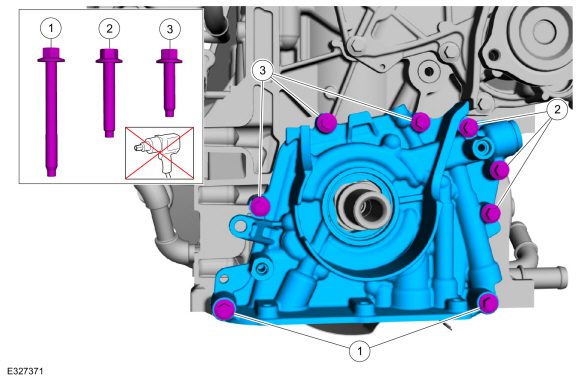

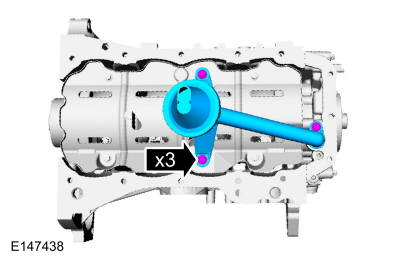

NOTE: Note the position of the 3 different lengths of the bolts for installation.

-

Remove the two M6 x 55 mm bolts.

-

Remove the three M6 x 35 mm bolts.

-

Remove the three M6 x 25 mm bolts and remove the oil pump.

-

Remove the two M6 x 55 mm bolts.

|

-

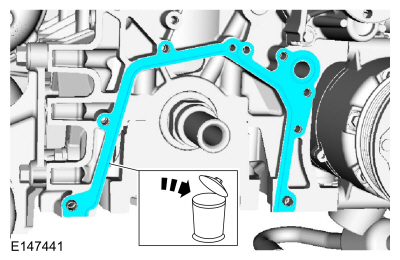

Remove and discard the oil pump gasket.

|

-

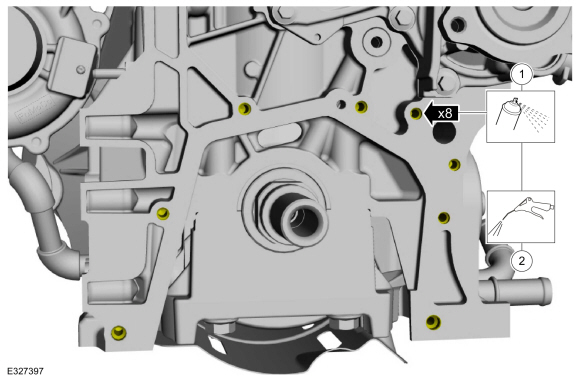

-

Clean the bolt holes for the oil pump with Motorcraft® Metal Brake Parts Cleaner to remove all residual oil.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Use compressed air to remove any brake clean or oil in the oil pump bolt holes.

-

Clean the bolt holes for the oil pump with Motorcraft® Metal Brake Parts Cleaner to remove all residual oil.

|

Installation

-

Install the new oil pump gasket.

|

-

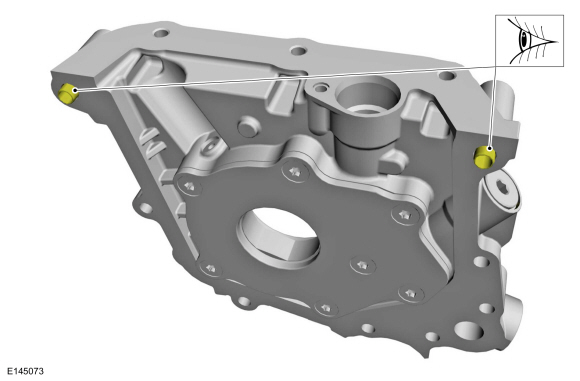

NOTE: Make sure that the locating dowels remain installed.

Inspect the oil pump locating dowels for damage and correct installation.

|

-

Prime the oil pump. Add 2 tablespoons of clean engine oil to the oil pump and rotate the oil pump by hand.

-

NOTE: Only tighten the bolts finger tight at this stage.

Install the oil pump and follow the steps below. Hand start the bolts.

-

Install the two M6 x 55 mm bolts finger tight.

-

Install the three M6 x 35 mm bolts finger tight.

-

Install the three M6 x 25 mm bolts finger tight.

-

Install the two M6 x 55 mm bolts finger tight.

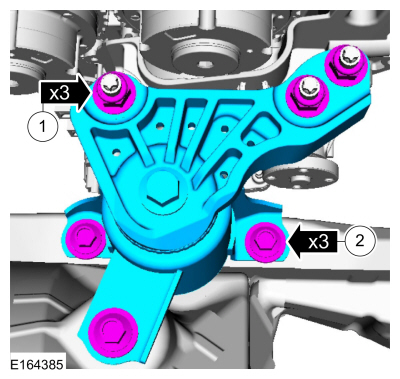

|

-

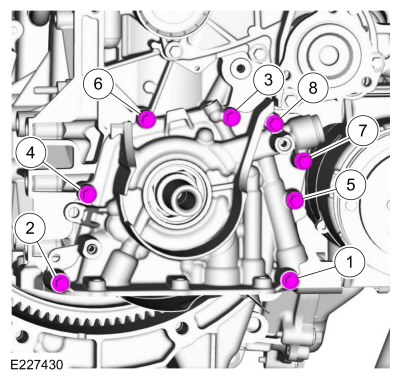

Tighten the oil pump bolts in sequence shown in 2 stages.

Torque:

Stage 1: Tighten bolts 1, 2, 3 and 6: 18 lb.in (2 Nm)

Stage 2: Tighten bolts 1 through 8: 97 lb.in (11 Nm)

|

-

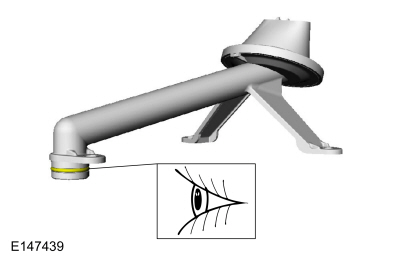

NOTE: The O-ring seal is to be reused unless damaged.

Inspect the O-ring seal, if necessary replace.

|

-

Install the oil pump screen and pickup tube and bolts.

Torque: 84 lb.in (9.5 Nm)

|

-

Install the oil pan.

Refer to: Oil Pan (303-01A Engine - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Removal and Installation).

-

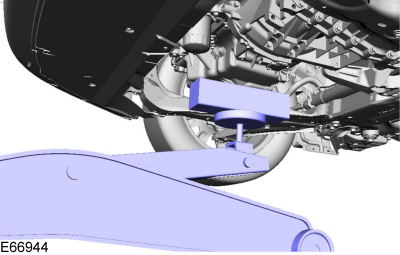

Support the engine.

Use the General Equipment: Trolley Jack

Use the General Equipment: Wooden Block

|

-

-

Remove the nuts.

-

Remove the bolts and the engine mount.

-

Remove the nuts.

|

-

Remove the engine mount stud.

|

-

NOTE: Note the different lengths of the bolts for installation.

Remove the bolts and the engine mount bracket.

|

- Install Special Service Tool: 303-1097 Locking Tool, Variable Camshaft Timing Oil Control Unit.

|

-

Install the crankshaft front seal.

Refer to: Crankshaft Front Seal (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Timing Belt. Removal and Installation

Timing Belt. Removal and Installation

Special Tool(s) /

General Equipment

303-1097Locking Tool, Variable Camshaft Timing Oil Control UnitTKIT-2010B-FLMTKIT-2010B-ROW

303-1550Alignment Tool, Crankshaft Vibration DamperTKIT-2012A-FLTKIT-2012A-ROW

303-393-02Adapter for 303-393TKIT-2012A-FLTKIT-2012A-ROW

303-393ALocking Tool, FlywheelTKIT-2012A-FLTKIT-2012A-ROW

303-748Locking Tool, C..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Sealer, Underbody Protection Material and Adhesives. Description and Operation

Adhesives NOTE: The following illustrations are examples of structural adhesive application and are not all inclusive. The correct adhesive bonding is essential to repairing the vehicle correctly. Adhesives are used in many areas of the body structure in place of welding. In addition to providing a structural bond between component, adhesives can also help prevent wind noise, wa..

Ford Fiesta 2014 - 2019 Service Manual: Oil Cooler. Removal and Installation

Special Tool(s) / General Equipment Strap Wrench Oil Drain Equipment Locking Pliers Materials Name Specification Engine Oil - SAE 5W-20 - Synthetic Blend Motor OilXO-5W20-Q1SP WSS-M2C945-B1 Removal NOTE: Removal steps in this procedure may contain installation details. With the vehicle in NEUTRAL, position i..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Engine Component View. Description and Operation

- Engine

- General Information

- Valve Clearance Adjustment. General Procedures

- Manual Transmission, Clutch, Transfer Case and Power Transfer Unit

Brake Drum. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).