Ford Fiesta: Fuel System - General Information - 1.6L EcoBoost (132kW/180PS) – Sigma / Spring Lock Couplings. General Procedures

Special Tool(s) / General Equipment

|

310-250 Disconnect Tool, Fuel Line TKIT-2012A-FL TKIT-2012A-ROW |

Disconnect

NOTICE: When reusing liquid or vapor tube connectors, make sure to use compressed air to remove any foreign material from the connector retaining clip area before separating from the tube or damage to the tube or connector retaining clip can occur. Apply clean engine oil to the end of the tube before inserting the tube into the connector.

NOTICE: Fuel injection equipment is manufactured to very precise tolerances and fine clearances. It is essential that absolute cleanliness is observed when working with these components or component damage can occur. Always install plugs to any open orifices or tubes.

-

If servicing a liquid fuel tube spring lock coupling, release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00B Fuel System - General Information - 1.6L EcoBoost (132kW/180PS) – Sigma, General Procedures).

-

Disconnect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

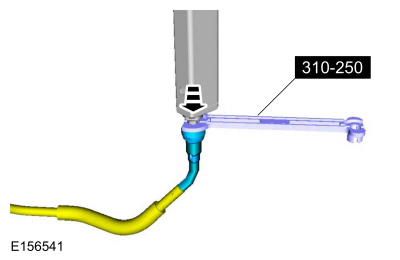

Install the Spring Lock Coupling Disconnect Tool on the tube and push into the spring lock coupling to release.

Use Special Service Tool: 310-250 Disconnect Tool, Fuel Line.

|

-

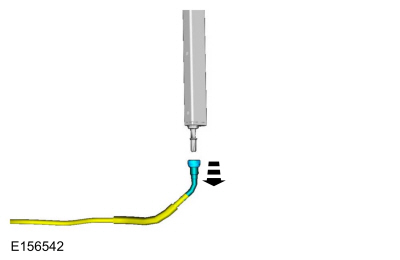

Separate the spring lock coupling from the tube.

|

Connect

-

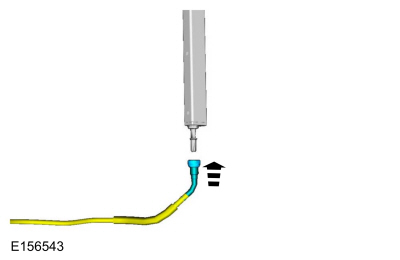

Align and push the spring lock coupling onto the tube until fully seated.

|

-

Pull on the coupling to make sure it is fully engaged.

-

Connect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Quick Release Coupling. General Procedures

Quick Release Coupling. General Procedures

Disconnect

NOTICE:

When reusing liquid or vapor tube connections, make sure to

use compressed air to remove any foreign material from the connector

retaining clip area before separating from the tube or damage to the

tube or connector retaining clip may occur...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Rear View Mirrors. Diagnosis and Testing

Symptom Chart(s) Symptom Chart: Rear View Mirrors - Exterior, Power Condition Possible Sources Actions Mirrors fold inward due to wind pressure Mirror structural bracket is damaged INSPECT the mirror for structural damage. If necessary, INSTALL a new mirror. REFER to: Exterior Mirror (501-09 Rear..

Ford Fiesta 2014 - 2019 Service Manual: Audio Unit Antenna Cable. Removal and Installation

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: The AM / FM /Satellite radio antenna cables are part of the vehicle wiring harness. Because the cables cannot be removed from the harness, this procedure applies to the replacement of the cables only. Front cable..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Climate Control System - General Information

- Front Suspension

- Manual Transmission - 6-Speed Manual Transmission – B6

- General Information

- Engine

Axle. Removal and Installation

Special Tool(s) / General Equipment

Flat Headed Screw Driver Transmission Jack Vehicle/Axle StandsRemoval

NOTICE: Suspension fasteners are critical parts that affect performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

Remove the floor console.Refer to: Floor Console (501-12 Instrum