Ford Fiesta: Body Repairs - General Information / Specifications

General Specifications

| Item | Specification |

|---|---|

| Plastic front fascia paint maximum thickness | 12 mils (300 microns) |

| Plastic rear fascia paint maximum thickness | 12 mils (300 microns) |

General Specifications

| Item | Specification |

|---|---|

| Plug Weld hole | 8 mm (0.315 in) |

| Weld Wire ER70S-3 | 0.9 mm (0.0354 in) - 1.1 mm (0.0433 in) |

| Weld Wire ER70S-6 | 0.9 mm (0.0354 in) - 1.1 mm (0.0433 in) |

Weld Nugget Chart

| Test Thickness of Metal | Nugget Size |

|---|---|

| 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) | 4.7 mm (0.185 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) | 4.7 mm (0.185 in) |

| 1 mm (0.0394 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 1 mm (0.0394 in) + 1 mm (0.0394 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 3 mm (0.1181 in) + 3 mm (0.1181 in) | 8.7 mm (0.3425 in) |

| 3 mm (0.1181 in) + 3 mm (0.1181 in) + 3 mm (0.1181 in) | 8.7 mm (0.3425 in) |

| 3 mm (0.1181 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.7 mm (0.0276 in) + 3 mm (0.1181 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) + 2 mm (0.0787 in) | 4.7 mm (0.185 in) |

| 2 mm (0.0787 in) + 0.9 mm (0.0354 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 1 mm (0.0394 in) + 3 mm (0.1181 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 3 mm (0.1181 in) + 1 mm (0.0394 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 0.9 mm (0.0354 in) + 0.7 mm (0.0276 in) + 0.9 mm (0.0354 in) | 4.3 mm (0.1693 in) |

Ford Recommended Steel Repairability Matrix

| Grade | Trade Descriptions | Welding Method | Cold Repairs | Use of Heat for Repair | Temperature Range | Maximum Heat | ||

|---|---|---|---|---|---|---|---|---|

| MAG | Squeeze-Type Resistance Spot Welding (STRW) | MAG Braze | ||||||

| Mild Steel | Mild | Yes | Yes | N/A | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Laminate Steel | Quiet Steel | No | Yes | No | Yesa | NA | NA | NA |

| Bake Hardened Steel (BH) | Bake Hardened Steel (BH) 180, 200, 210, 220, 250, 280 | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Solid Solution Strengthened | - | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| High-Strength Low Alloy (HSLA) | High-Strength Low Alloy (HSLA) 200, High-Strength Low Alloy (HSLA 250, High-Strength Low Alloy (HSLA 260, High-Strength Low Alloy (HSLA 300, High-Strength Low Alloy (HSLA 340, High-Strength Low Alloy (HSLA 350, High-Strength Low Alloy (HSLA 500, High-Strength Low Alloy (HSLA) 550 | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Dual Phase Steel (DP) | Dual Phase Steel (DP) 500, Dual Phase Steel (DP) 600 | Yes | Yes | Yesb | Yesa | No | NA | NA |

| Dual Phase Steel (DP)c | Dual Phase Steel (DP) 700, Dual Phase Steel (DP) 900 and Dual Phase Steel (DP) 1,000 | Yesd | Yes | Yesb | No | No | NA | NA |

| Ultra High Strength Steel (UHSS) (Martensitic, Boron)e | Boron, Martensitic | Yesa | Yes | Yesb | No | No | NA | NA |

| Transformation Induced Plasticity Steel (TRIP) | Transformation Induced Plasticity Steel (TRIP) 590, Transformation Induced Plasticity Steel (TRIP) 780, Transformation Induced Plasticity Steel (TRIP) 980 | NA | NA | NA | NA | NA | NA | NA |

aCold repairs can be performed if damage excludes kinks. May section only if approved procedure in workshop manual.

bMetal Active Gas (MAG) braze allowed for non-structural applications only.

cDual phase steels DP 700 class, DP 900 class and DP 1,000 class must be replaced at factory joints, no sectioning unless approved procedure in workshop manual.

dFor DP 900, 1,000 and Boron use Metal Active Gas (MAG) plug welding only, no stitch welding.

eBoron and Ultra High Strength Steel (UHSS)-Mortensite components must be replaced at factory joints, no sectioning allowed.

Health and Safety Precautions. Description and Operation

Health and Safety Precautions. Description and Operation

General

Appropriate

repair methods and their correct correct implementation are very

important for both vehicle operating safety and personal safety...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Pinpoint Test - DTC: G. Diagnosis and Testing

B0052:11, B0052:12, B0052:13 and B0052:1D Refer to Wiring Diagrams Cell 46 for schematic and connector information. Normal Operation and Fault Conditions The RCM monitors the passenger safety belt buckle switch circuits for the following faults: Open circuit Short to voltage Short to ground Current out of range Faulted passeng..

Ford Fiesta 2014 - 2019 Service Manual: Battery. Diagnosis and Testing

General Equipment Diagnostic Battery Charger Battery Condition Test Battery condition is determined by measuring battery terminal voltage after a specific discharge current is applied for a specified time period. Visual Inspection and Diagnostic Pre-checks Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Service Information

- Front Suspension

- Engine Component View. Description and Operation

- Fuel Rail. Removal and Installation

- Clutch - 6-Speed Manual Transmission – B6

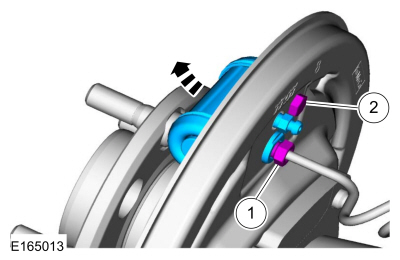

Brake Backing Plate. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the brake shoes.Refer to: Brake Shoes (206-02 Drum Brake, Removal and Installation).

Disconnect the brake tube fitting.

Torque: 159 lb.in (18 Nm) Remove the bolt and wheel cylinder.

Torque: 106 lb.in (12 Nm)

Disconnect the brake shoe lever fitting and re

Disconnect the brake shoe lever fitting and re