Ford Fiesta: Engine System - General Information / Flywheel Inspection - 1.6L EcoBoost (132kW/180PS) – Sigma. General Procedures

Inspection

NOTE: Do not clean the dual mass flywheel with compressed air.

NOTE: Do not clean the dual mass flywheel with any kind of fluid, use a dry cloth only or damage to the dual mass flywheel may occur.

NOTE: Do not clean the gap between the primary and secondary mass. Only clean the bolt connection surface and the clutch surface or damage to the dual mass flywheel may occur.

NOTE: The dual mass flywheel cannot be machined.

-

NOTE: The dual mass flywheel should be replaced if it has been scored by the clutch or if it has large cracks. Minor heat cracks and heat discoloration do not effect the function of the dual mass flywheel. The dual mass flywheel can be re-used if it has minor heat cracks or heat discoloration.

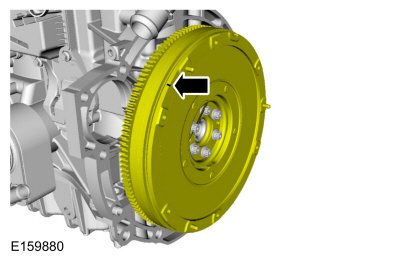

Inspect the clutch contact surface for damage.

-

If large cracks or scoring are found on the clutch contact surface, install a new dual mass flywheel.

Refer to: Flywheel (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

-

Minor heat cracks on the clutch contact surface is acceptable wear. Do NOT install a new dual mass flywheel.

-

Minor heat scoring on the clutch contact surface is

acceptable wear. Do NOT install a new dual mass flywheel.

-

If large cracks or scoring are found on the clutch contact surface, install a new dual mass flywheel.

|

-

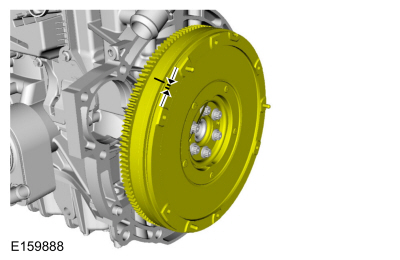

NOTE: This check should be done at room temperature.

NOTE: Move the secondary mass by hand right and left several times before proceeding with the freeplay check.

Place a reference mark on the secondary mass of the dual mass flywheel.

|

-

Using light hand pressure, rotate the secondary mass

clockwise to the end of the freeplay. Place a reference mark on the

primary mass of the dual mass flywheel, in line with the reference mark

on the secondary mass.

|

-

Using light hand pressure, rotate the secondary mass

counterclockwise to the end of the freeplay. Place a second reference

mark on the secondary mass of the dual mass flywheel, in line with the

reference mark on the primary mass.

|

-

Measure the rotational freeplay between the 2 reference

marks on the secondary mass of the dual mass flywheel. If the rotational

freeplay exceeds 10 mm (0.394 in), install a new dual mass flywheel.

|

-

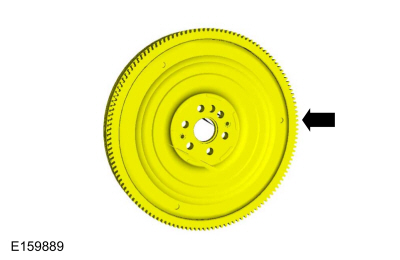

Inspect the dual mass flywheel ring gear. If the ring gear is damaged, install a new dual mass flywheel.

Refer to: Flywheel (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

|

-

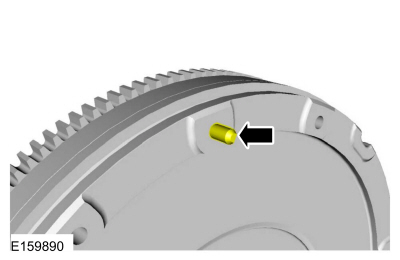

Inspect the dual mass flywheel guide pins. If the guide

pins are missing or different lengths, install a new dual mass flywheel.

Refer to: Flywheel (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

|

-

Inspect the transmission bell housing for traces of

grease. If there is an excessive amount of grease 46.4 mm (1.83 in) from

the front edge of the bell housing, install a new dual mass flywheel.

Refer to: Flywheel (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Exhaust Manifold Cleaning and Inspection. General Procedures

Exhaust Manifold Cleaning and Inspection. General Procedures

Special Tool(s) /

General Equipment

Feeler Gauge

Cleaning

Clean the exhaust manifold using a suitable solvent. Use

a plastic scraping tool to clean the gasket sealing surfaces...

Piston Diameter. General Procedures

Piston Diameter. General Procedures

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the piston diameter (at the measuring window) 90

degrees from the piston pin and 10 mm (...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Rear Window Glass Reseal - 4-Door. General Procedures

Materials Name Specification Sika® SikaTack® MACH 60 / Sika® SikaTack® MACH 30 / Dow® BETASEAL™ Express - Sika Tack ASAP Urethane Adhesive - Motorcraft® Ultra-Clear Spray Glass CleanerZC-23 ESR-M14P5-A Repair Remove the headliner...

Ford Fiesta 2014 - 2019 Service Manual: Condenser - 1.6L EcoBoost (132kW/180PS) – Sigma. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Recover the refrigerant. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information) ...

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Fuel Rail. Removal and Installation

- General Information

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Timing Belt. Removal and Installation

- Front Subframe. Removal and Installation

Ride Height Measurement. General Procedures

Special Tool(s) / General Equipment

Surface GaugeCheck

Ride Height Measurement - Front

NOTE: Make sure that the vehicle is positioned on a flat, level surface and the tires are inflated to the correct pressure. Vehicle should have a full tank of fuel.

Ride height = 2-3Measurement 2

Measurement 3

Use the General Equipment: Surface Gauge