Ford Fiesta: Suspension System - General Information / Ride Height Measurement. General Procedures

Ford Fiesta 2014 - 2019 Service Manual / Suspension / Suspension System - General Information / Ride Height Measurement. General Procedures

Special Tool(s) / General Equipment

| Surface Gauge |

Check

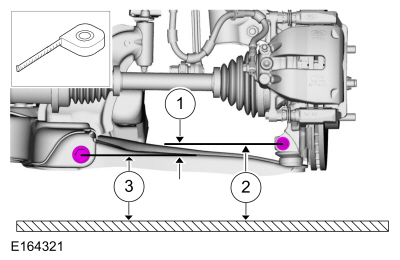

Ride Height Measurement - Front

NOTE: Make sure that the vehicle is positioned on a flat, level surface and the tires are inflated to the correct pressure. Vehicle should have a full tank of fuel.

-

-

Ride height = 2-3

-

Measurement 2

-

Measurement 3

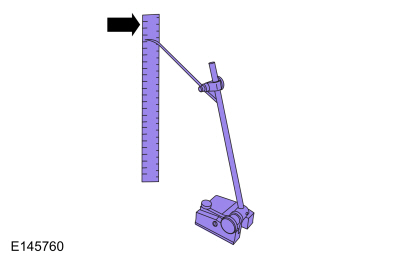

Use the General Equipment: Surface Gauge

-

Ride height = 2-3

|

-

With the surface gauge positioned on a flat, level

surface, record the measurement of the surface gauge position

(measurements 2 and 3).

Use the General Equipment: Surface Gauge

|

-

Subtract measurement 2 from measurement 3 to obtain the front ride height.

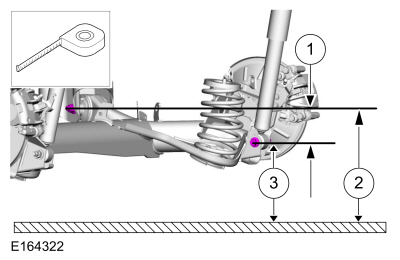

Ride Height Measurement - Rear

NOTE: Make sure that the vehicle is positioned on a flat, level surface and the tires are inflated to the correct pressure. Vehicle should have a full tank of fuel.

-

-

Ride height = 2-3

-

Measurement 2

-

Measurement 3

Use the General Equipment: Surface Gauge

-

Ride height = 2-3

|

-

Measure the distance between the flat level surface and the forward lower arm inboard bolt (measurement 2).

-

Measure the distance between the flat level surface

and the center of the forward lower arm outboard bolt (measurement 3).

-

Subtract measurement 3 from measurement 2 to obtain the rear ride height.

Suspension System. Diagnosis and Testing

Suspension System. Diagnosis and Testing

Preliminary Inspection

Road test the vehicle.

If any suspension alignment or ride height concerns are present, GO to Symptom Chart — Suspension System...

Front Toe Adjustment. General Procedures

Front Toe Adjustment. General Procedures

Special Tool(s) /

General Equipment

Wheel Alignment System

Adjustment

NOTE:

Make sure that the vehicle is standing on a level surface...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Air Deflector. Removal and Installation

Special Tool(s) / General Equipment Flat-Bladed Screwdriver Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: The roof opening panel glass must be in the fully open position...

Ford Fiesta 2014 - 2019 Service Manual: Clutch Pedal Position (CPP) Switch. Removal and Installation

Removal Top of travel switch Disconnect the electrical connector and remove CPP switch from the bracket. Bottom of travel switch Disconnect the electrical connector and remove CPP switch from the bracket...

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Timing Belt. Removal and Installation

- Manual Transmission, Clutch, Transfer Case and Power Transfer Unit

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Valve Clearance Adjustment. General Procedures

- Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma

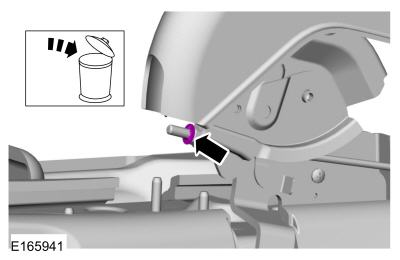

Parking Brake Control. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the floor console.Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Remove the driver seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Remove the parking brake cable adjustment lock nut.

Loosen the parking brake cable adjustment nut.

Loosen the parking brake cable adjustment nut.

Copyright © 2025 www.fofiesta7.com