Ford Fiesta: Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma / Engine Cooling System Draining, Vacuum Filling and Bleeding. General Procedures

Special Tool(s) / General Equipment

|

ROB75240 Coolant/Battery Refractometer (Fahrenheit) |

| Hose Clamp Remover/Installer | |

| Fluid Container | |

| Cooling System Vacuum Tester and Refiller | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Orange Prediluted Antifreeze/Coolant VC-3DIL-B |

WSS-M97B44-D2 |

| Motorcraft® Orange Concentrated Antifreeze/Coolant VC-3-B |

WSS-M97B44-D |

Draining

-

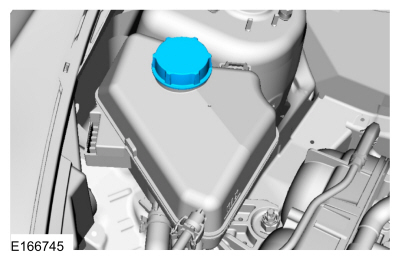

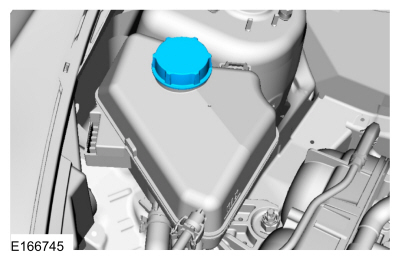

Release the cooling system pressure by slowly turning the coolant expansion tank cap between 2 and 3 turns. WARNING:

When releasing the cooling system pressure, cover the coolant expansion tank cap with a thick cloth.

WARNING:

When releasing the cooling system pressure, cover the coolant expansion tank cap with a thick cloth.

|

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

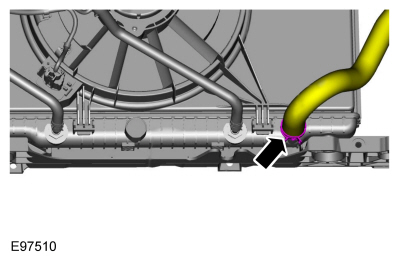

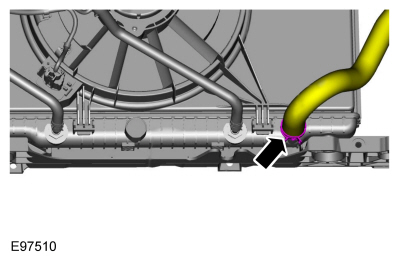

Release the clamp and disconnect the lower radiator hose. WARNING:

Be prepared to collect escaping fluid.

WARNING:

Be prepared to collect escaping fluid.

Use the General Equipment: Fluid Container

Use the General Equipment: Hose Clamp Remover/Installer

|

-

Connect the lower radiator hose and install the hose clamp.

Use the General Equipment: Hose Clamp Remover/Installer

|

Filling

NOTE: NOTE: Steps 7 through 19 is required to remove any remaining air pockets from the cooling system.

-

Install the vacuum cooling system filler and follow the

manufacturer's instructions to fill and bleed the system.

Use the General Equipment: Cooling System Vacuum Tester and Refiller

-

-

Measure the coolant concentration in the vehicle.

Use Special Service Tool: ROB75240 Coolant/Battery Refractometer (Fahrenheit).

-

Determine the concentration desired based on the

vehicle duty cycle of extreme hot or cold operating conditions.

-

Add, top-off or adjust the coolant as follows:

-

For concentrations measured 48/52 to 50/50 (freeze

protection -34˚C to -37˚C [-30˚F to -34˚F]) use Motorcraft® Orange

Antifreeze/Coolant Prediluted to maintain a coolant concentration in

this same range.

Material: Motorcraft® Orange Prediluted Antifreeze/Coolant / VC-3DIL-B (WSS-M97B44-D2)

-

For all other concentrations, use Motorcraft® Orange

Antifreeze/Coolant Concentrated and/or distilled water to get to the

desired concentration.

Material: Motorcraft® Orange Concentrated Antifreeze/Coolant / VC-3-B (WSS-M97B44-D)

-

When refilling the engine coolant after a flush

procedure, use a mixture of Motorcraft® Orange Antifreeze/Coolant

Concentrated and distilled water to get to the desired concentration.

-

Measure the coolant concentration in the vehicle.

-

Recommended coolant concentration is 48/52 to 50/50

engine coolant to distilled water (freeze protection -34˚C to -37˚C

[-30˚F to -34˚F]).

-

-

For extremely cold climates (less than -37˚C [-34˚F]):

-

It may be necessary to increase the coolant concentration above 50%.

-

NEVER increase the coolant concentration above 60%.

-

Maximum coolant concentration is 60/40 for cold weather areas.

-

A coolant concentration of 60% provides freeze protection down to -50˚C (-58˚F)

-

Engine coolant concentration above 60% will decrease

the overheat protection characteristics of the engine coolant and may

damage the engine.

-

For extremely cold climates (less than -37˚C [-34˚F]):

-

-

For extremely hot climates:

-

It is still necessary to maintain the coolant concentration above 40%.

-

NEVER decrease the coolant concentration below 40%.

-

Minimum coolant concentration is 40/60 for warm weather areas.

-

A coolant concentration of 40% provides freeze point protection down to the following temperature.

Temperature: -15 °F ( -26 °C)

-

Engine coolant concentration below 40% will decrease

the freeze protection characteristics of the engine coolant and may

damage the engine.

-

For extremely hot climates:

-

Vehicles driven year-round in non-extreme climates

should use a 48/52 to 50/50 (freeze protection -34˚C to -37˚C [-30˚F to

-34˚F]) mixture of engine coolant and distilled water for optimum

cooling system and engine protection.

-

Fill the degas bottle to the MAX FILL line.

-

Install the degas bottle cap until it contacts the hard stop.

-

Turn the climate control system off.

-

Start the engine and increase the engine speed to 3,500 rpm and hold for 30 seconds.

-

Turn the engine off for and wait for 1 minute to purge any large air pockets from the cooling system.

-

Check the engine coolant level in degas bottle and if necessary fill to the top of the MAX FILL line on the degas bottle if the engine is warm or to the top of the MIN FILL LEVEL if the engine is cold. WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

-

Start the engine and let it idle until the engine

reaches normal operating temperature and the thermostat is fully open. A

fully open thermostat is verified by the cooling fan cycling on at

least once.

-

Increase the engine speed to 3,500 rpm and hold for 30 seconds.

-

Allow the engine to idle for 30 seconds.

-

Turn the engine off for 1 minute.

-

Repeat steps 14 through 16 a total of 5 times to remove any remaining air trapped in the system.

-

Check the engine coolant level in degas bottle and if necessary fill to the top of the MAX FILL line on the degas bottle. WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

-

Install the pressure relief cap until it contacts the hard stop.

|

Block Heater. Removal and Installation

Block Heater. Removal and Installation

Materials

Name

Specification

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Removal

NOTE:

Removal steps in this procedure may contain installation details...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Battery and Cables - System Operation and Component Description. Description and Operation

System Operation Battery and Cables The battery is a 12V DC source connected in a negative ground system and is a voltage stabilizer for the 12V electrical system. Vehicles with 1.0L EcoBoost or 1.6L EcoBoost engine have a battery monitor sensor attached to the negative battery cable...

Ford Fiesta 2014 - 2019 Service Manual: Pinpoint Test - DTC: F. Diagnosis and Testing

B0050:11, B0050:12, B0050:13 and B0050:1D Refer to Wiring Diagrams Cell 46 for schematic and connector information. Normal Operation and Fault Conditions The RCM monitors the driver safety belt buckle switch circuits for the following faults: Open circuit Short to voltage Short to ground Current out of range Faulted driver saf..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Clutch - 6-Speed Manual Transmission – B6

- Camshafts. Removal and Installation

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine

- Front Strut and Spring Assembly. Removal and Installation

Axle. Removal and Installation

Special Tool(s) / General Equipment

Flat Headed Screw Driver Transmission Jack Vehicle/Axle StandsRemoval

NOTICE: Suspension fasteners are critical parts that affect performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

Remove the floor console.Refer to: Floor Console (501-12 Instrum