Ford Fiesta: Manual Transmission - 6-Speed Manual Transmission – B6 / Differential. Disassembly and Assembly of Subassemblies

Special Tool(s) / General Equipment

|

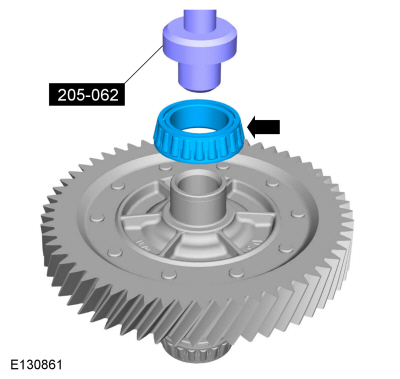

205-062 Installer, Differential Bearing |

| Puller | |

| Bearing Separator | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Dual Clutch Transmission Fluid XT-11-QDC |

WSS-M2C200-D2 |

DISASSEMBLY

NOTICE: Use vise jaw protectors.

-

Clamp the differential in a vise.

-

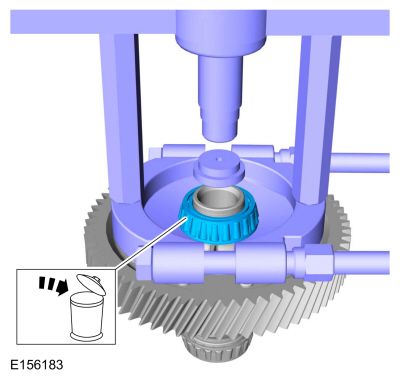

Remove the bearing.

Use the General Equipment: Bearing Separator

Use the General Equipment: Puller

|

-

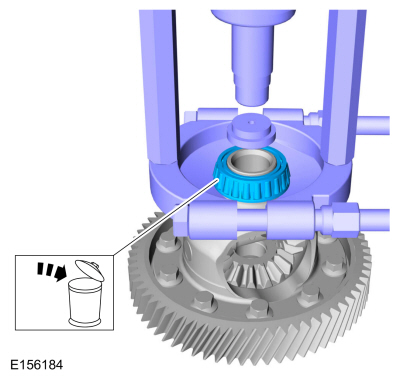

Remove the bearing.

Use the General Equipment: Bearing Separator

Use the General Equipment: Puller

|

-

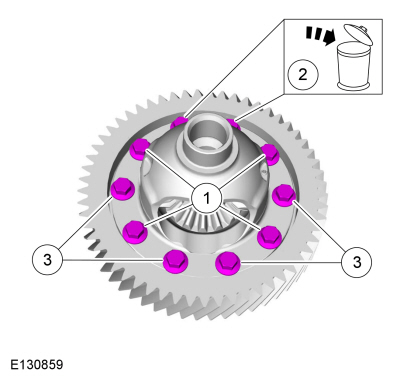

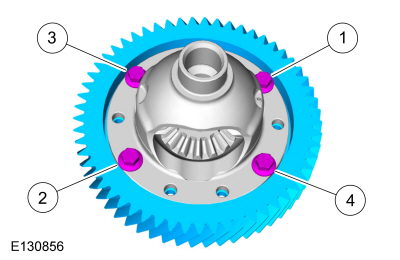

Remove the following items:

- Loosen: Four turn(s)

-

Remove and discard the bolts.

-

Save four bolts for reassembly.

|

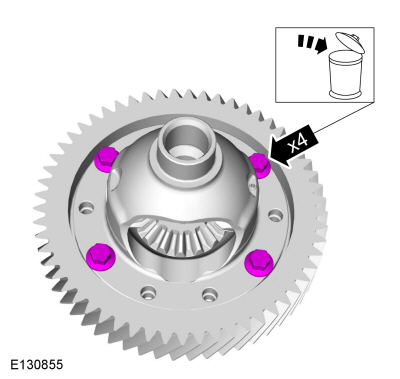

-

Lightly tap the bolts to remove the ring gear from the differential and remove the 4 bolts.

|

ASSEMBLY

-

NOTE: Do not lubricate new roller bearings.

Lubricate all other transmission components with transmission fluid during reassembly.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

NOTICE: Use vise jaw protectors.

-

Clamp the differential in a vise.

-

NOTE: Make sure that the mating faces are clean and free of foreign material.

-

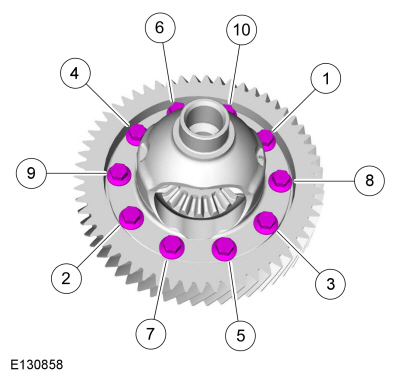

Install the four bolts saved during disassembly.

-

Tighten each bolt 1 turn at a time in the sequence shown.

Torque: 37 lb.ft (50 Nm)

-

Install the four bolts saved during disassembly.

|

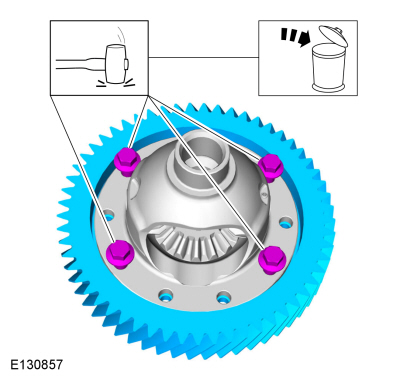

-

Remove and discard the bolts.

|

-

Install new bolts and tighten each bolt 1 turn at a time in the sequence shown.

Torque:

Stage 1: 37 lb.ft (50 Nm)

Stage 2: 90°

|

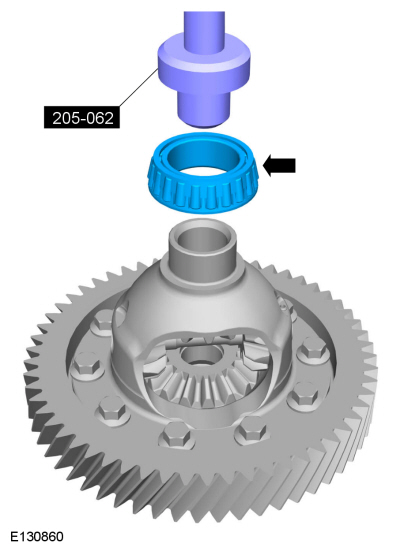

-

NOTE: The roller bearing must not be lubricated.

Install the bearing.

Use Special Service Tool: 205-062 Installer, Differential Bearing.

|

-

NOTE: The roller bearing must not be lubricated.

Install the bearing.

Use Special Service Tool: 205-062 Installer, Differential Bearing.

|

Transmission. Disassembly

Transmission. Disassembly

Special Tool(s) /

General Equipment

307-003

(T57L-500-B)

Holding Fixture, Transmission

Puller

Punch

WARNING:

Before beginning any service procedure in this section, refer to

Safety Warnings in section 100-00 General Information...

Input Shaft. Disassembly and Assembly of Subassemblies

Input Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) /

General Equipment

205-199

(T83T-3132-A1)

Installer, Spindle/Axle ShaftT83-4000-ATKIT-1983-FTKIT-1983-FLMTKIT-1983-FX

205-D015

(D80L-630-4)

Step Plate

211-014Remover, Steering Wheel

307-679Installer, Countershaft Needle BearingTKIT-2010D-FLMTKIT-2010D-ROW

Hydraulic Press

Hot Air Gun

Bearing Separator

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Clutch Slave Cylinder - 5-Speed Manual Transmission – B5/IB5. Removal and Installation

Removal Remove the transmission. Refer to: Transmission - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma (308-03A Manual Transmission - 5-Speed Manual Transmission – B5/IB5, Removal). Refer to: Transmission (308-03B Manual Transmission - 6-Speed Manual Transmission – B6, Removal). Remove the bolts and the clutch slave cylinder. Torque: 89 l..

Ford Fiesta 2014 - 2019 Service Manual: Hood Alignment. General Procedures

Inspection Check the body to the hood dimensions. Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation). Adjustment Right/Left and Fore/Aft Loosen the nuts to permit movement of the hood. Loosen: 2 turn(s) Loose..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Front Suspension

- Maintenance Schedules

- Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Camshafts. Removal and Installation

Axle. Removal and Installation

Special Tool(s) / General Equipment

Flat Headed Screw Driver Transmission Jack Vehicle/Axle StandsRemoval

NOTICE: Suspension fasteners are critical parts that affect performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

Remove the floor console.Refer to: Floor Console (501-12 Instrum