Ford Fiesta: Engine - 1.6L EcoBoost (132kW/180PS) – Sigma / Camshafts. Removal and Installation

Special Tool(s) / General Equipment

|

303-1532 Installer, Camshaft Seal TKIT-2010B-FLM TKIT-2010B-ROW |

|

303-393-02 Adapter for 303-393 TKIT-2012A-FL TKIT-2012A-ROW |

|

303-393A Locking Tool, Flywheel TKIT-2012A-FL TKIT-2012A-ROW |

|

303-409

(T92C-6700-CH)

Remover, Crankshaft Seal TKIT-1992-FH/FMH/FLMH TKIT-1993-LMH/MH |

|

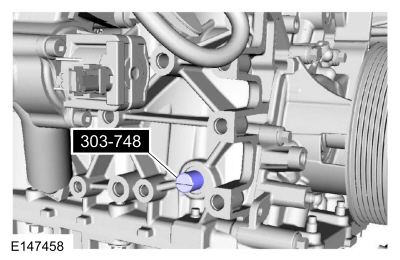

303-748 Locking Tool, Crankshaft TKIT-2010B-FLM TKIT-2010B-ROW |

| Feeler Gauge | |

| Hot Air Gun | |

Materials

| Name | Specification |

|---|---|

| Flange Sealant CU7Z-19B508-A |

WSS-M2G348-A11 |

| Motorcraft® Metal Surface Prep Wipes ZC-31-B |

- |

| Engine Oil - SAE 5W-20 - Synthetic Blend Motor Oil XO-5W20-Q1SP |

WSS-M2C945-B1 |

Removal

NOTICE: During engine repair procedures, cleanliness is extremely important. Any foreign material (including any material created while cleaning gasket surfaces) that enters the oil passages, coolant passages or the oil pan can cause engine failure.

NOTICE: Do not rotate the camshafts unless instructed to in this procedure. Rotating the camshafts or crankshaft with timing components loosened or removed can cause serious damage to the valves and pistons.

-

Remove the VCT units.

Refer to: Variable Camshaft Timing (VCT) Unit (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

-

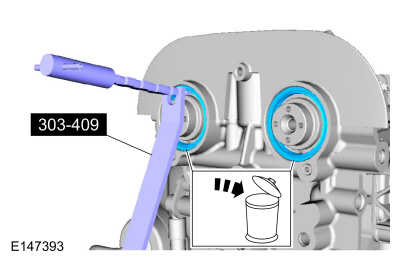

Using the special tools, remove the camshaft seals.

Use Special Service Tool: 303-409 (T92C-6700-CH) Remover, Crankshaft Seal.

|

-

NOTICE: Use a heat gun to soften the flange sealant, this will aid in the removal of the camshaft mega cap. Failure to follow these directions may result in damage to the camshaft mega cap.

NOTE: Note the location and orientation of each camshaft bearing cap and the position of the camshaft lobes on the No. 1 cylinder for installation reference.

-

Remove the bolts and the camshaft caps and discard the bolts.

-

Heat the mega cap and remove.

Use the General Equipment: Hot Air Gun

-

Remove the camshafts.

-

Remove the bolts and the camshaft caps and discard the bolts.

|

-

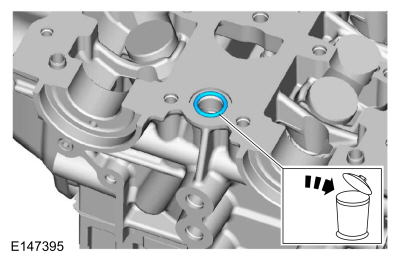

Remove and discard the O-ring seal.

|

-

Make sure that the mating faces are clean and free of foreign material.

Material: Motorcraft® Metal Surface Prep Wipes / ZC-31-B

|

-

Make sure that the mating faces are clean and free of foreign material.

Material: Motorcraft® Metal Surface Prep Wipes / ZC-31-B

|

Installation

-

NOTICE: If any new parts are being installed (cylinder head, valves, tappets, camshafts) it is necessary to check the valve clearance, follow the next 12 steps exactly or serious damage to the engine may occur. If the original parts are being installed it is not necessary to check the valve clearance so proceed to step 13.

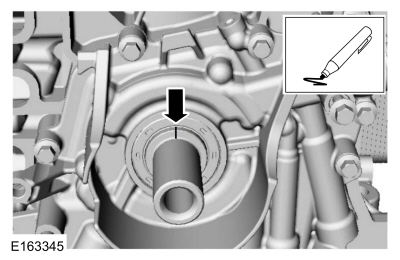

Place a paint mark on the crankshaft at the 12 o'clock position.

|

- Remove Special Service Tool: 303-393A Locking Tool, Flywheel. , 303-393-02 Adapter for 303-393.

|

- Remove Special Service Tool: 303-748 Locking Tool, Crankshaft.

|

-

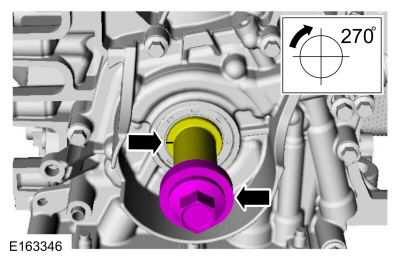

NOTE: Rotating the crankshaft will position all of the pistons below the deck of the cylinder block and allow the camshafts to be installed and the valve clearance checked without the possibility of damage to the valves or pistons.

Using the crankshaft bolt and washer, rotate the crankshaft clockwise 270 degrees until the paint mark is at the 9 o'clock position.

|

-

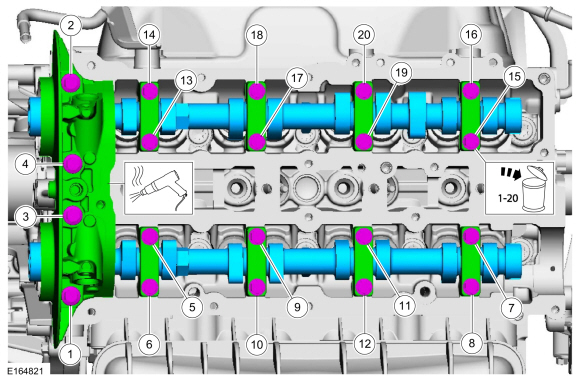

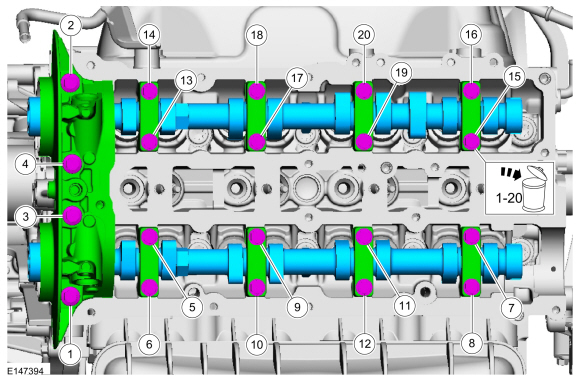

NOTICE: Failure to follow the camshaft tightening procedure can result in damage to the camshafts.

NOTE: Make sure that the components are installed to the location and orientation noted before removal.

NOTE: Make sure that the mating faces are clean and free of foreign material.

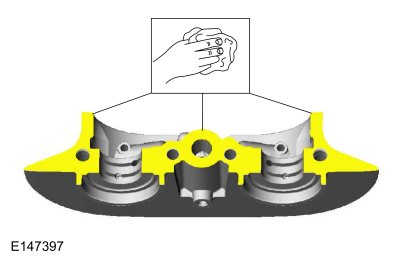

NOTE: Apply clean engine oil to the bearing surfaces of the camshafts, camshaft bearing caps and the VCT bridge.

Tighten the bolts evenly, half a turn at a time, until the camshaft bearing caps and the VCT bridge are seated against the cylinder head.

Material: Engine Oil - SAE 5W-20 - Synthetic Blend Motor Oil / XO-5W20-Q1SP (WSS-M2C945-B1)

Torque:

Stage 1: Tighten bolts 1 through 16 to:: 62 lb.in (7 Nm)

Stage 2: Tighten bolts 17 through 20 to:: 89 lb.in (10 Nm)

Stage 3: Tighten bolts 1 through 16 an additional:: 45°

Stage 4: Tighten bolts 17 and 18 an additional:: 70°

Stage 5: Tighten bolts 19 and 20 an additional:: 53°

|

-

-

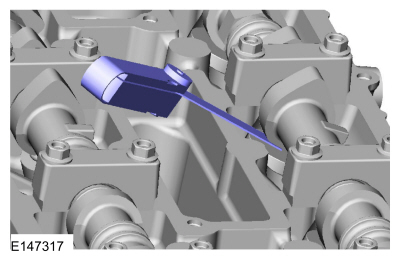

Using the flats of the camshaft, rotate the camshaft

to place the cam lobe at base circle, with the lobe pointed away from

the tappet.

-

Use a feeler gauge to measure the clearance of each valve and record its location.

Use the General Equipment: Feeler Gauge

-

Repeat to measure all of the lobe/tappet clearances.

-

Using the flats of the camshaft, rotate the camshaft

to place the cam lobe at base circle, with the lobe pointed away from

the tappet.

|

-

NOTE: Select tappets using this formula: ideal tappet thickness = measured clearance + the existing tappet thickness - nominal clearance. Select the closest tappet size to the ideal tappet thickness available and mark the installation location.

NOTE: The nominal clearance is:

- intake: 0.0118 in (0.3 mm)

- exhaust: 0.0157 in (0.4 mm)

NOTE: The acceptable clearances after being fully installed are:

- intake: 0.010–0.014 in (0.255–0.345 mm)

- exhaust: 0.014–0.018 in (0.355–0.445 mm)

-

NOTICE: Failure to follow the camshaft loosening procedure can result in damage to the camshafts.

NOTE: Note the location and orientation of each camshaft bearing cap and the position of the camshaft lobes on the No. 1 cylinder for installation reference.

Loosen the camshaft bearing caps in sequence 2 turns at a time until all tension is released from the camshaft bearing caps in sequence shown.

|

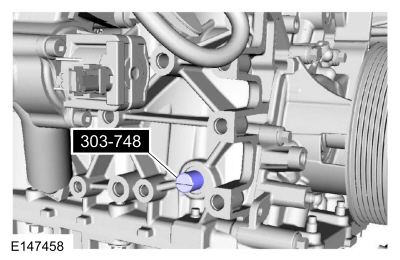

- Install Special Service Tool: 303-748 Locking Tool, Crankshaft.

|

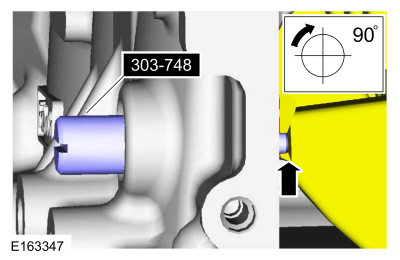

-

NOTE: Rotating the crankshaft will position the engine at TDC and allow you to install the camshafts in the same position as noted during the disassembly.

Rotate the crankshaft clockwise 90 degrees so the crankshaft contacts the crankshaft timing peg.

|

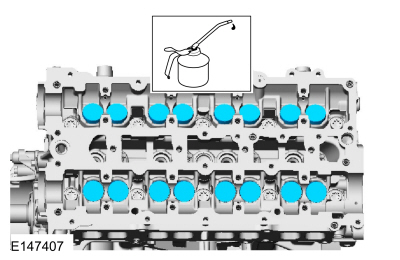

-

NOTE: Lubricate the tappets with clean engine oil.

If necessary, replace any tappets with the correct tappets selected during the valve clearance check.

Material: Engine Oil - SAE 5W-20 - Synthetic Blend Motor Oil / XO-5W20-Q1SP (WSS-M2C945-B1)

|

-

NOTE: Verify the crankshaft contacts the Timing Peg and the engine is still at TDC

Install Special Service Tool: 303-393A Locking Tool, Flywheel. , 303-393-02 Adapter for 303-393.

|

-

Install a new O-ring seal.

|

-

NOTE: The component must be installed within 5 minutes of applying the sealant.

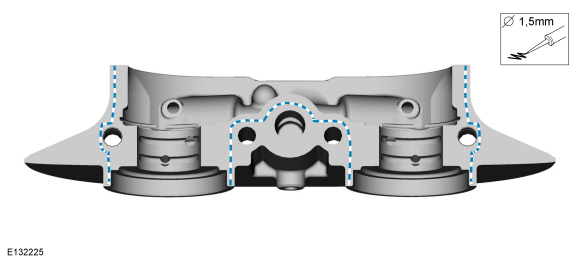

Apply flange sealant as shown.

Material: Flange Sealant / CU7Z-19B508-A (WSS-M2G348-A11)

|

-

NOTICE: Failure to follow the camshaft tightening procedure can result in damage to the camshafts.

NOTE: Make sure that the components are installed to the location and orientation noted before removal.

NOTE: Make sure that the mating faces are clean and free of foreign material.

NOTE: Apply clean engine oil to the bearing surfaces of the camshafts, camshaft bearing caps and the VCT bridge.

NOTE: Make sure that new bolts are installed.

Tighten the bolts evenly, half a turn at a time, until the camshaft bearing caps and the VCT bridge are seated against the cylinder head.

Material: Engine Oil - SAE 5W-20 - Synthetic Blend Motor Oil / XO-5W20-Q1SP (WSS-M2C945-B1)

Torque:

Stage 1: Tighten bolts 1 through 16 to:: 62 lb.in (7 Nm)

Stage 2: Tighten bolts 17 through 20 to:: 89 lb.in (10 Nm)

Stage 3: Tighten bolts 1 through 16 an additional:: 45°

Stage 4: Tighten bolts 17 and 18 an additional:: 70°

Stage 5: Tighten bolts 19 and 20 an additional:: 53°

|

-

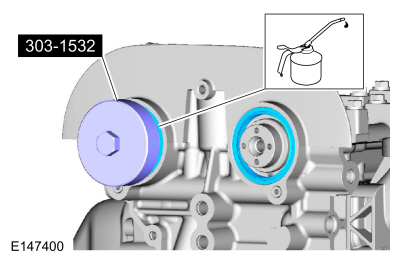

Lubricate with clean engine oil and using the special tool, install the camshaft seals.

Use Special Service Tool: 303-1532 Installer, Camshaft Seal.

Material: Engine Oil - SAE 5W-20 - Synthetic Blend Motor Oil / XO-5W20-Q1SP (WSS-M2C945-B1)

|

-

Install the VCT units.

Refer to: Variable Camshaft Timing (VCT) Unit (303-01B Engine - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Crankshaft Rear Seal. Removal and Installation

Crankshaft Rear Seal. Removal and Installation

Removal

Remove the following items:

Remove the flywheel.

Refer to: Flywheel (303-01A Engine - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Removal and Installation)...

Cylinder Head. Removal and Installation

Cylinder Head. Removal and Installation

Special Tool(s) /

General Equipment

Strap Wrench

Oil Drain Equipment

Hose Clamp Remover/Installer

Materials

Name

Specification

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Engine Oil - SAE 5W-20 - Synthetic Blend Motor OilXO-5W20-Q1SP

WSS-M2C945-B1

Removal

Refer to: Jacking and Lifting - Over..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Rear Door Skin Panel. Removal and Installation

Special Tool(s) / General Equipment Grinder Hot Air Gun Knife MIG/MAG Welding Equipment Locking Pliers Materials Name Specification Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 - Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM - Flexible Foam Repai..

Ford Fiesta 2014 - 2019 Service Manual: Audio Front Control Module (ACM). Removal and Installation

Removal NOTE: If the ACM did not respond to the diagnostic scan tool, As-Built Data may need to be entered as part of the repair. NOTE: This step is only necessary when installing a new component. NOTE: The PMI process must begin with the current ACM installed. If the current ACM does not respond to the diagnostic scan tool, the tool may prompt for As-Built Data a..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Fuel Pump. Removal and Installation

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Front Strut and Spring Assembly. Removal and Installation

- Engine System - General Information

- Maintenance Schedules

Front Strut and Spring Assembly. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

NOTE: This step is only necessary when installing a new component to the left-hand side.

Remove the nuts and position aside the remote brake fluid reservoir.Torque: 62 lb.in (7 Nm)

Remove the strut and spring assembly upper mount nuts.

Remove the strut and spring assembly upper mount nuts. Torque: 22 lb.ft (30 Nm)