Ford Fiesta: Steering Wheel and Column Electrical Components / Steering Wheel and Column Electrical Components. Diagnosis and Testing

DTC Charts

BCM DTC Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| DTC | Description | Action |

|---|---|---|

| B1142:13 | Ignition Status 1: Circuit Open | GO to Pinpoint Test L |

| All other Diagnostic Trouble Codes (DTCs) | - |

REFER to: Body Control Module (BCM) (419-10 Multifunction Electronic Modules, Diagnosis and Testing). |

IPC DTC Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| DTC | Description | Action |

|---|---|---|

| U300E:00 | Ignition Input On: No Sub Type Information | GO to Pinpoint Test L |

| U300F:00 | Ignition Input Accessory: No Sub Type Information |

|

| U3010:01 | Ignition Input Start: General Electrical Failure | GO to Pinpoint Test M |

| All other Diagnostic Trouble Codes (DTCs) | - |

REFER to: Instrumentation, Message Center and Warning Chimes (413-01 Instrumentation, Message Center and Warning Chimes, Diagnosis and Testing). |

RFA Module DTC Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| DTC | Description | Action |

|---|---|---|

| B108B:23 | Start Button Circuit "A": Signal Stuck Low | GO to Pinpoint Test H |

| B108B:29 | Start Button Circuit "A": Signal Invalid | GO to Pinpoint Test H |

| B108C:23 | Start Button Circuit "B": Signal Stuck Low | GO to Pinpoint Test H |

| B10E7:11 | Ignition On Relay: Circuit Short to Ground | GO to Pinpoint Test I |

| B10E7:12 | Ignition On Relay: Circuit Short to Battery | GO to Pinpoint Test I |

| B10E7:16 | Ignition On Relay: Circuit Voltage Below Threshold | GO to Pinpoint Test I |

| B10E7:17 | Ignition On Relay: Circuit Voltage Above Threshold | GO to Pinpoint Test I |

| U3004:11 | Accessory Power Relay: Circuit Short to Ground | GO to Pinpoint Test J |

| U3004:12 | Accessory Power Relay: Circuit Short to Battery | GO to Pinpoint Test J |

| U300E:62 | Ignition Input On: Signal Compare Failure | GO to Pinpoint Test K |

| U300F:62 | Ignition Input Accessory: Signal Compare Failure | GO to Pinpoint Test K |

| U3010:62 | Ignition Input Start: Signal Compare Failure | GO to Pinpoint Test K |

| U3011:62 | Ignition Input Off: Signal Compare Failure | GO to Pinpoint Test K |

| All other Diagnostic Trouble Codes (DTCs) | - |

REFER to: Remote Function Actuator (RFA) Module (419-10 Multifunction Electronic Modules, Diagnosis and Testing). |

Symptom Chart

Symptom Chart: Steering Column Switches

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart

| Condition | Possible Sources | Actions |

|---|---|---|

| No power in all ignition switch positions - conventional ignition switch |

|

|

| No power in ACC - conventional ignition switch |

|

|

| No power in ON - conventional ignition switch |

|

|

| No power in START - conventional ignition switch |

|

|

| No power in ON - push button ignition switch |

|

|

| KEY NOT DETECTED is displayed |

|

|

| The ignition key cylinder cannot be returned to the OFF position |

|

|

| The ignition key cylinder can be turned to the OFF position when the selector lever is not in PARK |

|

|

| The key cannot be removed from the ignition lock cylinder |

|

|

| The ignition key is hard to turn |

|

|

Pinpoint Tests

No Power in All Ignition Switch Positions - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The ignition switch receives fused battery voltage from CJB fuse 1 (15A). The ignition switch distributes this voltage to various electrical systems depending on the ignition switch position.

Possible Causes

- Fuse

- Wiring, terminals or connectors

- Ignition switch

Visual Inspection and Diagnostic Pre-checks

- Inspect the CJB fuse 1 (15A).

- Inspect BJB fuse 5 (60A).

PINPOINT TEST A: NO POWER IN ALL IGNITION SWITCH POSITIONS - CONVENTIONAL IGNITION SWITCH

| A1 CHECK THE HIGH CURRENT VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| A2 CHECK THE IGNITION SWITCH VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

No Power in ACC - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition switch is in the ACC position, voltage is provided through CJB fuse 19 (7.5A) to the IPC , signaling the ignition system is in ACC mode. The IPC sends a message over the CAN to indicate the ignition ACC mode to other modules on the network.

IPC DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U300F:00 | Ignition Input Accessory: No Sub Type Information | Sets when the IPC detects the ignition transitions from OFF to ON and no voltage is detected from the ACC input circuit. |

Possible Causes

- Fuse

- Wiring, terminals or connectors

- Ignition switch

PINPOINT TEST B: NO POWER IN ACC - CONVENTIONAL IGNITION SWITCH

| B1 CHECK THE IGNITION SWITCH ACC CIRCUIT FOR VOLTAGE | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| B2 CHECK THE IPC (INSTRUMENT PANEL CLUSTER) ACC INPUT CIRCUIT FOR AN OPEN TO THE IPC (INSTRUMENT PANEL CLUSTER) | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| B3 CHECK THE IGNITION SWITCH ACC CIRCUIT FOR AN OPEN | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| B4 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||||||||

Is the concern still present?

|

No Power in ON - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition switch is in the ON position, it provides voltage to the CJB fuses 20 (10A), 21 (7.5A), 22 (7.5A), 23 (7.5A) and to the coil side of the ignition relay. When the ignition relay energizes, it provides voltage to a variety of other vehicle systems.

The switch side of the ignition relay receives fused battery voltage from the BJB fuse 7 (60A). When the ignition relay energizes, it provides voltage to the remaining vehicle electrical systems that require power only when the ignition switch is in the ON position.

Possible Causes

- Wiring, terminals or connectors

- Ignition relay

- Ignition switch

Visual Inspection and Diagnostic Pre-checks

- Inspect BJB fuse 7 (60A).

- Inspect the ignition relay.

PINPOINT TEST C: NO POWER IN ON - CONVENTIONAL IGNITION SWITCH

| C1 CHECK THE IGNITION RELAY | ||||||||||||||||

Is the concern still present?

|

||||||||||||||||

| C2 CHECK THE IGNITION RELAY SWITCH BJB (BATTERY JUNCTION BOX) SUPPLY CIRCUIT FOR AN OPEN | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| C3 CHECK FOR VOLTAGE TO THE IGNITION RELAY COIL | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| C4 CHECK THE IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||

| C5 CHECK THE IGNITION RELAY GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||

Is the resistance less than 3 ohms?

|

No Power in START - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition switch is turned to the START position, voltage is sent through a single circuit to the IPC and the PCM indicating a request to start the vehicle. This circuit does not provide voltage to power any of the vehicle systems.

Possible Sources

- Starting system concern

PINPOINT TEST D: NO POWER IN START - CONVENTIONAL IGNITION SWITCH

| D1 CHECK FOR A STARTING SYSTEM CONCERN | ||||

Does the vehicle start?

|

No Power in ON - Push-Button Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition is in the ON mode, the RFA module provides voltage to the coil side of the smart keyless entry ignition relay and the smart keyless entry accessory relay. When the smart keyless entry ignition relay energizes, battery voltage is provided to the ignition relay and several fuses in the CJB . The ignition relay provides power to activate the remaining vehicle electrical systems. When the smart keyless entry accessory relay energizes, battery voltage is provided to CJB fuse 19 (7.5A) for the IPC to recognize the ignition accessory input circuit.

In the event the vehicle does not enter ON or the vehicle does not start, the FCDIM may display a message to indicate a possible cause.

Possible Causes

- Wiring, terminals or connectors

- Ignition relay

- Ignition switch

Visual Inspection and Diagnostic Pre-checks

- Inspect the BJB fuse 7 (60A).

- Inspect the ignition relay.

PINPOINT TEST E: NO POWER IN ON - PUSH-BUTTON IGNITION SWITCH

| E1 CHECK THE PASSIVE ENTRY FEATURE OPERATION | ||||||||||

Does the passive entry feature operate?

|

||||||||||

| E2 CHECK FOR THE NO KEY DETECTED MESSAGE | ||||||||||

Is the NO KEY DETECTED message displayed?

|

||||||||||

| E3 CHECK FOR IGNITION ON MODE | ||||||||||

Does the FCDIM display power up?

|

||||||||||

| E4 CHECK FOR COMMUNICATION WITH THE RFA (REMOTE FUNCTION ACTUATOR) MODULE | ||||||||||

Does the RFA module pass the network test?

|

||||||||||

| E5 CHECK FOR RFA (REMOTE FUNCTION ACTUATOR) MODULE DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||||||||

| E6 CHECK THE PUSH-BUTTON IGNITION SWITCH (START_SW_1 AND START_SW_2) PARAMETER IDENTIFICATIONS (PIDS) | ||||||||||

Do the Parameter Identifications (PIDs) change when the START/STOP button is pressed and released?

|

||||||||||

| E7 CHECK THE PUSH-BUTTON IGNITION SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| E8 CHECK FOR SMART KEYLESS ENTRY IGNITION RELAY OUTPUT | ||||||||||

|

NOTE: The previous step indicates the RFA module has changed the ignition state to ON.

Are any indicators illuminated in the IPC ?

|

||||||||||

| E9 CHECK FOR RFA (REMOTE FUNCTION ACTUATOR) MODULE SMART KEYLESS ENTRY IGNITION RELAY DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||||||||

| E10 CHECK FOR IPC (INSTRUMENT PANEL CLUSTER) DTC (DIAGNOSTIC TROUBLE CODE) U300F:00 | ||||||||||

Is DTC U300F:00 present?

|

||||||||||

| E11 CHECK THE IGNITION RELAY | ||||||||||

Is the concern still present?

|

||||||||||

| E12 CHECK THE IGNITION RELAY SWITCH BJB (BATTERY JUNCTION BOX) VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| E13 CHECK THE IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| E14 CHECK THE IGNITION RELAY GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| E15 CHECK FOR CORRECT RFA (REMOTE FUNCTION ACTUATOR) MODULE OPERATION | ||||||||||

Is the concern still present?

|

The Ignition Key Cylinder Cannot Be Returned to the OFF Position

Refer to Wiring Diagrams Cell 37 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Steering Wheel and Column Electrical Components - System

Operation and Component Description (211-05 Steering Wheel and Column

Electrical Components, Description and Operation).

Possible Causes

- Wiring, terminals or connectors

- Ignition switch

- Ignition lock cylinder

- Selector lever assembly

- IPC

PINPOINT TEST F: THE IGNITION KEY CYLINDER CANNOT BE RETURNED TO THE OFF POSITION

| F1 CHECK FOR AN ENERGIZED KEY REMOVAL INHIBIT SOLENOID | ||||||||||

Does the ignition lock cylinder rotate to the OFF-LOCK position and the key removed?

|

||||||||||

| F2 CHECK THE IGNITION SWITCH FOR MECHANICAL DAMAGE | ||||||||||

Does the ignition lock cylinder rotate to the OFF-LOCK position and can the key be removed?

|

||||||||||

| F3 CHECK THE KEY REMOVAL INHIBIT SOLENOID CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| F4 ISOLATE THE IPC (INSTRUMENT PANEL CLUSTER) | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| F5 CHECK THE KEY REMOVAL INHIBIT SOLENOID CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| F6 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||

Is the concern still present?

|

The Ignition Key Cylinder Can Be Turned to the OFF Position When the Selector Lever is Not in PARK

Refer to Wiring Diagrams Cell 37 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Steering Wheel and Column Electrical Components - System

Operation and Component Description (211-05 Steering Wheel and Column

Electrical Components, Description and Operation).

Possible Causes

- Wiring, terminals or connectors

- Ignition switch

- Selector lever

PINPOINT TEST G: THE IGNITION KEY CYLINDER CAN BE TURNED TO THE OFF POSITION WHEN THE SELECTOR LEVER IS NOT IN PARK

| G1 CHECK THE KEY INHIBIT SOLENOID CIRCUIT FOR CONTINUITY TO GROUND | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| G2 CHECK THE KEY INHIBIT SOLENOID CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| G3 CHECK THE SELECTOR LEVER ASSEMBLY GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

B108B:23, B108:29 or B108C:23

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Steering Wheel and Column Electrical Components - System

Operation and Component Description (211-05 Steering Wheel and Column

Electrical Components, Description and Operation).

The push-button ignition switch is a momentary, dual-contact, normally-open switch. The push-button ignition switch inputs are monitored by the RFA module by 2 circuits. When the START/STOP button is pressed, both contacts close and both voltage signals are routed to ground. The 2 circuits are for redundancy. If there is a concern with one of the 2 inputs, the other input provides a ground signal to allow the vehicle to start and a DTC sets.

RFA Module DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B108B:23 | Start Button Circuit "A": Signal Stuck Low | Pressing the start/stop switch starts a 120 second timer in the RFA module. This DTC sets when the RFA module detects the signal from C3503B-23 is still pulled low (switched to ground) when the timer expires. Holding the start/stop button pressed for more than 120 seconds can cause this DTC to set. This DTC only sets continuous; not during a module self-test. |

| B108B:29 | Start Button Circuit "A": Signal Invalid | When RFA module detects 5 occurrences of the push-button start ignition switch inputs not corresponding to each other, such as an open in one of the input circuits, this DTC sets. This DTC only sets continuous; not during a module self-test. |

| B108C:23 | Start Button Circuit "B": Signal Stuck Low | Pressing the start/stop switch starts a 120 second timer in the RFA module. This DTC sets when the RFA module detects the signal from C3503B-22 is still pulled low (switched to ground) when the timer expires. Holding the start/stop button pressed for more than 120 seconds can cause this DTC to set. This DTC only sets continuous; not during a module self-test. |

Possible Causes

- Wiring, terminals or connectors

- Push-button ignition switch

- RFA module

PINPOINT TEST H: B108B:23, B108:29 OR B108C:23

| H1 CHECK THE PUSH-BUTTON IGNITION SWITCH | ||||||||||||||||

Does the push-button ignition switch pass the component test?

|

||||||||||||||||

| H2 CHECK THE RFA (REMOTE FUNCTION ACTUATOR) MODULE START/STOP INPUT CIRCUITS FOR AN OPEN | ||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||

| H3 CHECK THE RFA (REMOTE FUNCTION ACTUATOR) MODULE START/STOP INPUT CIRCUIT A FOR A SHORT TO GROUND | ||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||

| H4 CHECK FOR CORRECT RFA (REMOTE FUNCTION ACTUATOR) MODULE OPERATION | ||||||||||||||||

Is the concern still present?

|

B10E7:11, B10E7:12, B10E7:16 or B10E7:17

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Steering Wheel and Column Electrical Components - System

Operation and Component Description (211-05 Steering Wheel and Column

Electrical Components, Description and Operation).

The RFA module controls and monitors the coil and switched output sides of the smart keyless entry ignition relay. When the RFA module activates the ignition ON mode, it activates the relay providing power to the main ignition relay and to the vehicle electrical systems.

RFA Module DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B10E7:11 | Ignition On Relay: Circuit Short To Ground | Sets when the RFA module detects a short to ground from the smart keyless entry ignition relay coil circuit. |

| B10E7:12 | Ignition On Relay: Circuit Short To Battery | Sets when the RFA module detects a short to voltage from the smart keyless entry ignition relay coil circuit. |

| B10E7:16 | Ignition On Relay: Circuit Voltage Below Threshold | Sets when the RFA module does not detect voltage from the smart keyless entry ignition relay output when it has activated the relay. |

| B10E7:17 | Ignition On Relay: Circuit Voltage Above Threshold | Sets when the RFA module detects voltage from the smart keyless entry ignition relay output when it has not activated the relay. |

Possible Causes

- Wiring, terminals or connectors

- Smart keyless entry ignition relay

- RFA module

Visual Inspection and Diagnostic Pre-checks

- Inspect the CJB fuse 1 (15A).

PINPOINT TEST I: B10E7:11, B10E7:12, B10E7:16 OR B10E7:17

| I1 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY | ||||||||||

Is the DTC still present?

|

||||||||||

| I2 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| I3 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO BATTERY VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| I4 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO THE SMART KEYLESS ENTRY IGNITION RELAY OUTPUT CIRCUIT | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| I5 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| I6 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY COIL GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| I7 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY BATTERY VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| I8 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY OUTPUT CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| I9 CHECK THE SMART KEYLESS ENTRY IGNITION RELAY OUTPUT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| I10 CHECK FOR CORRECT RFA (REMOTE FUNCTION ACTUATOR) MODULE OPERATION | ||||||||||

Is the concern still present?

|

U3004:11 or U3004:12

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Steering Wheel and Column Electrical Components - System

Operation and Component Description (211-05 Steering Wheel and Column

Electrical Components, Description and Operation).

The RFA module controls and monitors the coil side of the smart keyless entry accessory relay. When the smart keyless entry accessory relay is energized, voltage is provided to the IPC for the ignition ACC mode input.

RFA Module DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U3004:11 | Accessory Power Relay: Circuit Short To Ground | Sets when the RFA module detects a short to ground from the keyless entry accessory relay coil circuit. |

| U3004:12 | Accessory Power Relay: Circuit Short To Battery | Sets when the RFA module detects a short to voltage from the keyless entry accessory relay coil circuit. |

Possible Causes

- Wiring, terminals or connectors

- Smart keyless entry accessory relay

- RFA module

PINPOINT TEST J: U3004:11 OR U3004:12

| J1 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY | ||||||||||

Is the DTC still present?

|

||||||||||

| J2 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| J3 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| J4 CHECK FOR CORRECT RFA (REMOTE FUNCTION ACTUATOR) MODULE OPERATION | ||||||||||

Is the concern still present?

|

U300E:62, U300F:62, U300F:00, U3010:62 or U3011:62

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The RFA module monitors the push-button ignition switch. When the START/STOP button is pressed, the RFA module changes the ignition state (OFF to ON or ON to OFF). After receiving this input, the RFA module activates/deactivates the smart keyless entry ignition relay and the smart keyless entry accessory relay.

The IPC receives voltage input on separate circuits from the 2 smart keyless entry relays. Based on the input, the IPC sends an ignition status message to the RFA module over the CAN . The RFA module compares its current ignition state with the ignition status data from the IPC . If a discrepancy exists, a DTC sets.

RFA Module DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U300E:62 | Ignition Input On: Signal Compare Failure | Sets when the RFA module commanded ignition state does not match the IPC ignition status message received. This can be caused by a communication issue between the IPC and the RFA module, a wiring concern in the ignition input to the IPC or the RFA module or a failure in either module. |

| U300F:62 | Ignition Input Accessory: Signal Compare Failure | |

| U3010:62 | Ignition Input Start: Signal Compare Failure | |

| U3011:62 | Ignition Input Off: Signal Compare Failure |

IPC DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U300F:00 | Ignition Input Accessory: No Sub Type Information | Sets when the IPC detects the ignition has transitioned from OFF to ON and no voltage is detected from the ACC input circuit. |

Possible Causes

- Fuse

- Wiring, terminals or connectors

- Smart keyless entry accessory relay

- IPC

- RFA module

Visual Inspection and Diagnostic Pre-checks

- Inspect the CJB fuse 19 (7.5A).

PINPOINT TEST K: U300E:62, U300F:62, U300F:00, U3010:62 OR U3011:62

| K1 CARRY OUT THE NETWORK TEST | ||||||||||

Does the IPC pass the network test?

|

||||||||||

| K2 CHECK FOR RFA (REMOTE FUNCTION ACTUATOR) MODULE DTC (DIAGNOSTIC TROUBLE CODE) B10E7:16 | ||||||||||

Is DTC B10E7:16 present?

|

||||||||||

| K3 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY | ||||||||||

Is the DTC still present?

|

||||||||||

| K4 CHECK FOR IPC (INSTRUMENT PANEL CLUSTER) DTC (DIAGNOSTIC TROUBLE CODE) U300E:00, U300F:00 OR U3010:01 | ||||||||||

Is DTC U300E:00, U300F:00 or U3010:01 present?

|

||||||||||

| K5 VERIFY THE DTC (DIAGNOSTIC TROUBLE CODE) SETTING CONDITION | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| K6 CHECK THE IPC (INSTRUMENT PANEL CLUSTER) ACCESSORY INPUT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| K7 ISOLATE THE IPC (INSTRUMENT PANEL CLUSTER) ACCESSORY INPUT OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| K8 CHECK THE SMART KEYLESS ENTRY ACCESSORY BATTERY VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| K9 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY COIL GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| K10 CHECK THE SMART KEYLESS ENTRY ACCESSORY RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| K11 CHECK THE STARTING SYSTEM FOR CORRECT OPERATION | ||||||||||

Does the vehicle start?

|

||||||||||

| K12 CHECK THE IPC (INSTRUMENT PANEL CLUSTER) ACCESSORY INPUT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| K13 ISOLATE THE IPC (INSTRUMENT PANEL CLUSTER) ACCESSORY INPUT SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| K14 CHECK THE RFA (REMOTE FUNCTION ACTUATOR) MODULE START REQUEST CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| K15 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| K16 CHECK FOR CORRECT RFA (REMOTE FUNCTION ACTUATOR) MODULE OPERATION | ||||||||||

Is the concern still present?

|

B1142:13 or U300E:00

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

For vehicles with a conventional ignition switch, the BCM and the IPC share ignition ON status over the CAN . When the ignition status is ON, they also monitor an ignition ON input circuit for voltage. If the CAN message does not match the input circuit status, a DTC sets.

For vehicles with a push-button ignition switch, the BCM and the IPC receive ignition ON status from the RFA module over the CAN . When the ignition status is ON, they also monitor an ignition ON input circuit for voltage. If the CAN message does not match the input circuit status, a DTC sets.

BCM IPC DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B1142:13 | Ignition Status 1: Circuit Open | Sets when the BCM receives a message from the IPC or RFA module indicating the ignition state is on and the input from the ignition ON circuit does not correspond (such as an open circuit). |

IPC DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U300E:00 | Ignition Input On: No Sub Type Information | Sets when the IPC receives a message from the RFA module indicating the ignition state is on and the input from the ignition ON circuit does not correspond (such as an open circuit). |

Possible Causes

- Fuse

- Wiring, terminals or connectors

- IPC

- BCM

Visual Inspection and Diagnostic Pre-checks

- Inspect the CJB fuse 21 (7.5A).

PINPOINT TEST L: B1142:13 OR U300E:00

| L1 VERIFY THE CONCERN IS PRESENT | ||||||||||

Is BCM DTC B1142:13 or IPC DTC U300E:00 present?

|

||||||||||

| L2 CHECK THE IGNITION ON INPUT CIRCUIT FOR AN OPEN TO THE BCM (BODY CONTROL MODULE) | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| L3 CHECK THE IGNITION ON INPUT CIRCUIT FOR AN OPEN TO THE IPC (INSTRUMENT PANEL CLUSTER) | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| L4 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| L5 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

U3010:01

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The IPC monitors various circuits and performs certain checks during the self-test. If voltage from the ignition switch START input is detected during the IPC self-test, a DTC sets.

IPC DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| U3010:01 | Ignition Input Start: General Electrical Failure | Sets when the IPC detects voltage from the ignition START input circuit during the IPC self-test. |

Possible Causes

- Wiring, terminals or connectors

- IPC

PINPOINT TEST M: U3010:01

| M1 CHECK THE IPC (INSTRUMENT PANEL CLUSTER) IGNITION START INPUT CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| M2 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||

Is the concern still present?

|

Steering Column Multifunction Switch LH. Removal and Installation

Steering Column Multifunction Switch LH. Removal and Installation

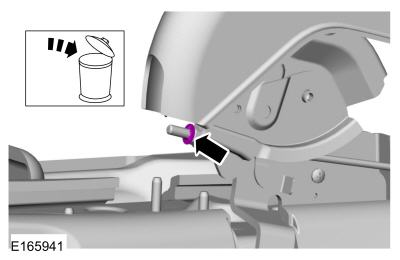

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the upper steering column shroud.

Remove the screws and the lower steering column shroud...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Brake Pedal Position (BPP) Switch Adjustment. General Procedures

Adjustment NOTICE: Do not press the brake pedal when installing or removing the brake pedal position switch or damage to the brake pedal-mounted switches can occur. Inspect all brake pedal position switches and brake pedal assembly to verify there is no brake pedal pressure unintentionally applied due to incorrect brake pedal position switch or brake pedal installat..

Ford Fiesta 2014 - 2019 Service Manual: Fog Lamps. Diagnosis and Testing

DTC Chart: BCM BCM DTC Chart DTC Description Action B1046:23 Front Fog Lamp Control Switch: Signal Stuck Low GO to Pinpoint Test C B1A78:12 Front Fog Lamp: Circuit Short To Battery GO to Pinpoint Test A ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Engine Component View. Description and Operation

- Fuel Rail. Removal and Installation

- General Information

- Engine. Assembly

- Maintenance Schedules

Parking Brake Control. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the floor console.Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Remove the driver seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Remove the parking brake cable adjustment lock nut.

Loosen the parking brake cable adjustment nut.

Loosen the parking brake cable adjustment nut.

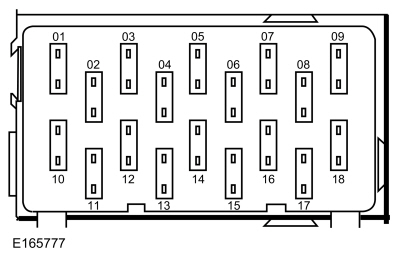

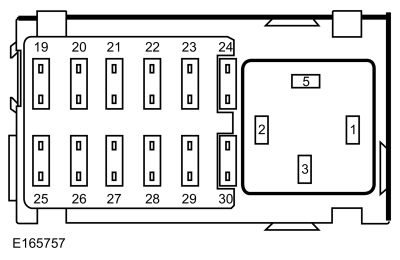

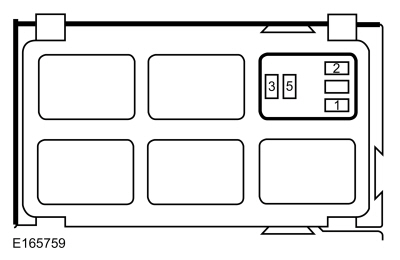

CJB fuse 1 (15A)

CJB fuse 1 (15A)

CJB fuse 19 (7.5A)

CJB fuse 19 (7.5A)

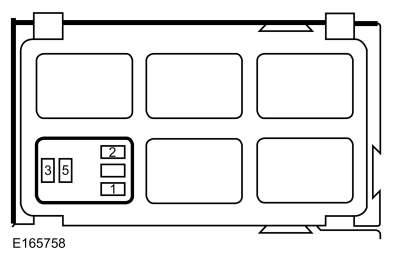

Smart keyless entry ignition relay, cavity 1

Smart keyless entry ignition relay, cavity 1

Smart keyless entry accessory relay, cavity 5

Smart keyless entry accessory relay, cavity 5