Ford Fiesta: Engine System - General Information / RTV Sealing Surface Cleaning and Preparation. General Procedures

Special Tool(s) / General Equipment

| Plastic Scraper | |

| Nylon Bristle Disk | |

| Plastic Razor Blade | |

| Lint-Free Towel | |

| Isopropyl Alcohol – 90 Percent Minimum |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Silicone Gasket Remover ZC-30-A, AZC-30-C |

- |

| Motorcraft® Metal Surface Prep Wipes ZC-31-B |

- |

| Motorcraft® Engine Shampoo and Degreaser ZC-20, AZC-20-C |

ESR-M14P3-A |

| Motorcraft® Metal Brake Parts Cleaner PM-4-A, PM-4-B, APM-4-C |

- |

Cleaning

NOTICE: This procedure is only to be used on the sealing surfaces of metal components. Do not use this procedure on non-metal (composite/plastic) components. Failure to follow this direction can lead to malfunction of the RTV seal and fluid leakage.

NOTICE: Place clean, lint-free towels over exposed cavities. Carefully remove the towels so foreign material is not dropped into the cavities. Any foreign material (including any material created while cleaning surfaces) that enters the fluid passages, may cause failure.

NOTICE: Do not use metal scrapers, wire brushes, power sanding or grinding discs, or any abrasive means other than what is specified in this procedure to clean sealing surfaces. These tools cause scratches and gouges which make leak paths.

NOTICE: The use of latex gloves is recommended. Using latex gloves will minimize the risk of contaminating RTV sealing surfaces and a leak.

NOTE: Bristle discs are acceptable to use for parts that are removed from the engine and vehicle and can be thoroughly washed and cleaned of debris caused by the tool itself and any other debris before installing the part on the engine.

NOTE: Click here to view a video version of the RTV Sealing Surface Cleaning and Preparation procedure.

RTV Sealing Surface Cleaning and Preparation procedure

-

NOTE: The order of use of materials to clean surfaces in this procedure is as follows:

- Material: Motorcraft® Silicone Gasket Remover / ZC-30-A, AZC-30-C

- Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Use the specified product or a commercially available equivalent.

Material: Motorcraft® Engine Shampoo and Degreaser / ZC-20, AZC-20-C (ESR-M14P3-A)

- Material: Motorcraft® Metal Surface Prep Wipes / ZC-31-B

-

NOTE: This step is to help prevent contamination of an RTV sealing surface from drain down after it has been prepared.

For oil pan repairs where residual engine oil in the crankcase may drain down and contaminate a prepared sealing surface, spray the interior of the engine block, skirt stiffener and drain back ports with Brake Cleaner to flush away any excess residual oil. Use a lint-free towel to remove the remainder of the bulk oil cleaner from the components.

Use the General Equipment: Lint-Free Towel

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Remove loose sealant by hand or with the aid of a plastic scraper or plastic razor blade.

Use the General Equipment: Plastic Scraper

Use the General Equipment: Plastic Razor Blade

-

Apply Gasket Remover to surface. Allow material to work for several minutes.

Material: Motorcraft® Silicone Gasket Remover / ZC-30-A, AZC-30-C

-

Use a lint-free towel and plastic scraper or plastic

razor blade to remove any remaining sealant. Use additional Gasket

Remover, as required.

Use the General Equipment: Lint-Free Towel

Use the General Equipment: Plastic Scraper

Use the General Equipment: Plastic Razor Blade

Material: Motorcraft® Silicone Gasket Remover / ZC-30-A, AZC-30-C

-

For parts that are removed from the engine and vehicle

that can be thoroughly cleaned without the risk of contaminating the

engine with debris, use a bristle disc grade 120 to clean the sealing

surface.

Use the General Equipment: Nylon Bristle Disk

-

-

For oil pan repairs, spray the interior of the

engine block, skirt stiffener and drain back ports with Brake Cleaner to

flush away any additional residual oil.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Use a lint-free towel to remove the remainder of the bulk oil and cleaner from the components.

Use the General Equipment: Lint-Free Towel

-

Clean the RTV sealing surface with Brake Cleaner to remove all residual sealant and oil.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Wipe the RTV sealing surface dry with a clean lint-free towel.

Use the General Equipment: Lint-Free Towel

-

Inspect and make certain there are no oil contaminants on the sealing surface before proceeding to step 7.

-

For oil pan repairs, spray the interior of the

engine block, skirt stiffener and drain back ports with Brake Cleaner to

flush away any additional residual oil.

-

NOTICE: Engine Shampoo and Degreaser is used to remove residual brake cleaner which can cause RTV failure and prepare the surface for the Metal Surface Prep Wipes. The use of any other brand engine shampoo or engine cleaner can compromise the sealing surface and could lead to failure of the RTV seal and a fluid leak.

Use Engine Shampoo and Degreaser to clean the surface of any remaining oil contamination and prepare the surface for the Metal Surface Prep Wipes. After Engine Shampoo and Degreaser, dry the surface with a clean lint-free towel.

Use the General Equipment: Lint-Free Towel

Material: Motorcraft® Engine Shampoo and Degreaser / ZC-20, AZC-20-C (ESR-M14P3-A)

-

NOTICE: Metal Surface Prep Wipes can only be applied to a dry surface. Failure to dry the sealing surface before using Metal Surface Prep Wipes can result in a failure of the RTV seal and a fluid leak.

NOTE: Metal Surface Prep Wipes is a pre-saturated, wet disposable wipe to be used as a final step in surface preparation. The wipe fluid creates a conversion coating providing an improved base for RTV sealing. The fluid should be allowed to dry in place. It does not require rinsing.

NOTE: Discard wipe after a single use.

Prep the surface with Metal Surface Prep Wipes. All metal surfaces to be sealed with RTV are to be wiped. Make sure the entire surface is moistened with the fluid.

Material: Motorcraft® Metal Surface Prep Wipes / ZC-31-B

-

NOTICE: Drying the surface with a towel will contaminate the surface and may cause oil leaks.

NOTICE: If the metal sealing surface or an area of the metal sealing surface becomes contaminated after it has been prepared, or if fluid from the Metal Surface Prep Wipe beads up on the sealing surface, use a lint-free towel soaked in isopropyl alcohol to clean the area. Prepare the area again using Metal Surface Prep Wipes.

Allow the fluid applied to the metal sealing surface to air dry. (Approximately 2 minutes.)

Use the General Equipment: Isopropyl Alcohol – 90 Percent Minimum

Powertrain/Drivetrain Mount Neutralizing. General Procedures

Powertrain/Drivetrain Mount Neutralizing. General Procedures

Adjustment

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

Remove the battery tray...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Catalytic Converter. Removal and Installation

Special Tool(s) / General Equipment Cable Ties Removal NOTE: Exhaust fasteners are of a torque prevailing design. Use only new fasteners with the same part number as the original. Torque values must be used as specified during reassembly to make sure of correct retention of exhaust components. NOTE: Removal steps in this procedure may contain installation d..

Ford Fiesta 2014 - 2019 Service Manual: Engine Coolant Temperature (ECT) Sensor. Removal and Installation

Materials Name Specification Motorcraft® Orange Prediluted Antifreeze/CoolantVC-3DIL-B WSS-M97B44-D2 Removal NOTE: Removal steps in this procedure may contain installation details. Remove air cleaner outlet pipe. Refer to: Air Cleaner Outlet Pipe (303-12B Intake Air Distribution and Filtering - 1.6L EcoBoost (132kW/180PS) – Sigma, ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Timing Belt. Removal and Installation

- Fuel Pump. Removal and Installation

- Maintenance Schedules - Gasoline Engines. Description and Operation

- Engine Component View. Description and Operation

- Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma

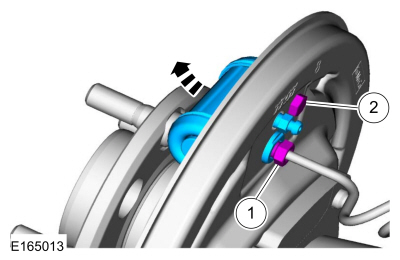

Brake Backing Plate. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the brake shoes.Refer to: Brake Shoes (206-02 Drum Brake, Removal and Installation).

Disconnect the brake tube fitting.

Torque: 159 lb.in (18 Nm) Remove the bolt and wheel cylinder.

Torque: 106 lb.in (12 Nm)

Disconnect the brake shoe lever fitting and re

Disconnect the brake shoe lever fitting and re