Ford Fiesta: Manual Transmission - 6-Speed Manual Transmission – B6 / Reverse Gear Output Shaft. Disassembly and Assembly of Subassemblies

Ford Fiesta 2014 - 2019 Service Manual / Manual Transmission, Clutch, Transfer Case and Power Transfer Unit / Manual Transmission - 6-Speed Manual Transmission – B6 / Reverse Gear Output Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) / General Equipment

|

205-D015

(D80L-630-4)

Step Plate |

|

205-D016

(D80L-630-5)

Step Plate |

|

307-679 Installer, Countershaft Needle Bearing TKIT-2010D-FLM TKIT-2010D-ROW |

|

308-416 Remover/Installer, Thrust Washer Bearing Cup TKIT-1999A-F/LT TKIT-1999A-FM/FLM |

| Hydraulic Press | |

| Puller | |

| Bearing Separator | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Dual Clutch Transmission Fluid XT-11-QDC |

WSS-M2C200-D2 |

DISASSEMBLY

-

Remove the bearing.

Use the General Equipment: Bearing Separator

Use the General Equipment: Puller

|

-

Remove the bearing.

Use the General Equipment: Bearing Separator

Use the General Equipment: Puller

|

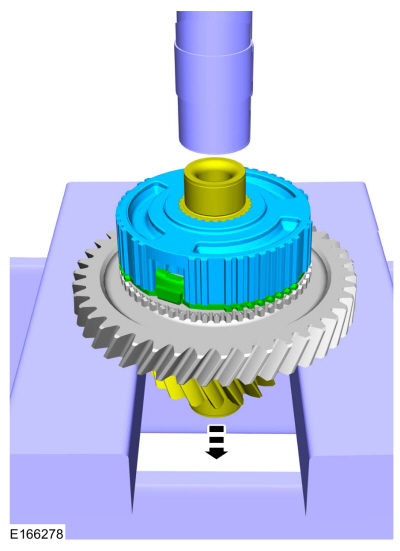

-

Remove the reverse gear synchronizer ring and the synchronizer body.

Use Special Service Tool: 205-D015 (D80L-630-4) Step Plate.

Use the General Equipment: Hydraulic Press

|

-

Remove the reverse gear and the needle bearing.

|

ASSEMBLY

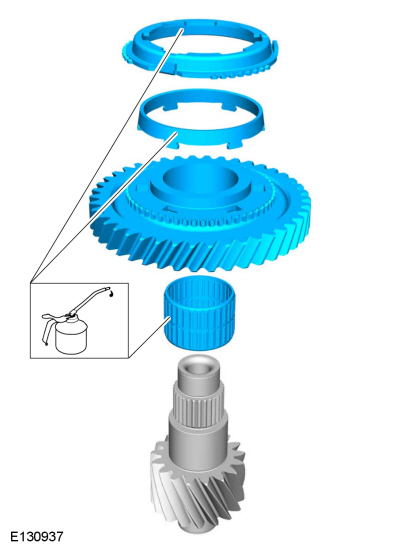

-

Lubricate the reverse gear friction rings.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

|

-

Install the reverse gear synchronizer ring and the

synchronizer body. Make sure the tab on the upper friction ring aligns

with the opening in the synchronizer body and the tabs on the lower

friction ring fit into the reverse gear.

Use Special Service Tool: 308-416 Remover/Installer, Thrust Washer Bearing Cup.

|

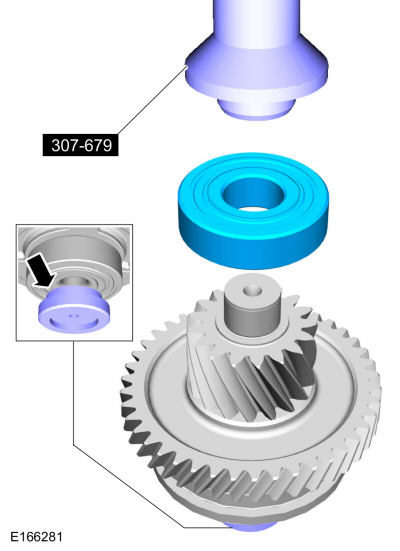

-

Install the bearing.

Use Special Service Tool: 307-679 Installer, Countershaft Needle Bearing.

Use the General Equipment: Hydraulic Press

|

-

Install the bearing.

Use Special Service Tool: 307-679 Installer, Countershaft Needle Bearing. , 205-D016 (D80L-630-5) Step Plate.

Use the General Equipment: Hydraulic Press

|

Transmission. Assembly

Transmission. Assembly

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

205-075Installer, Rear Wheel Hub Seal

205-081AInstaller, Differential Bearing

205-115Installer, Drive Pinion SealTKIT-2000-F/FM/FLM

303-350

(T89P-6565-A)

Compressor, Valve SpringTKIT-1990-LMHTKIT-1989-FTKIT-1989-FMTKIT-1989-FLM

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Rear Suspension - Overview. Description and Operation

Overview Characteristics of rear axle: Twist-beam axle (torsionally rigid axle) Single-pipe gas shock absorbers with stable damping performance for optimum handling Axle suspension uses large rubber bushes for optimum ride comfort Function If compression takes place on both wheels evenly (for example when a load is placed on the vehicle), the who..

Ford Fiesta 2014 - 2019 Service Manual: Fuel Tank Pressure Sensor and Tube. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation). Disconnect the battery. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures). ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Engine System - General Information

- Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine. Assembly

- Manual Transmission - 6-Speed Manual Transmission – B6

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

Component Bleeding. General Procedures

Special Tool(s) / General Equipment

Master Cylinder Bleeding SetBleeding

NOTICE: If the fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water.

Master Cylinder

NOTE: When a new brake master cylinder has been installed, it should be primed to prevent air from entering the system.

NOTE: Make sure the area around the master cylinder cap is clean and free of foreign material.

Remove the brake fluid reservoir cap.Copyright © 2025 www.fofiesta7.com