Ford Fiesta: Engine - 1.6L EcoBoost (132kW/180PS) – Sigma / Engine. Disassembly

Special Tool(s) /

General Equipment

|

100-001

(T50T-100-A)

Slide Hammer |

|

300-OTC1819E

2,200# Floor Crane, Fold Away |

|

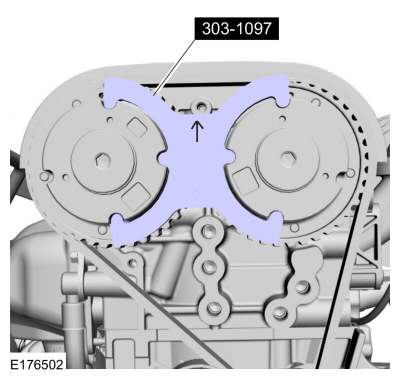

303-1097

Locking Tool, Variable Camshaft Timing Oil Control Unit

TKIT-2010B-FLM

TKIT-2010B-ROW |

|

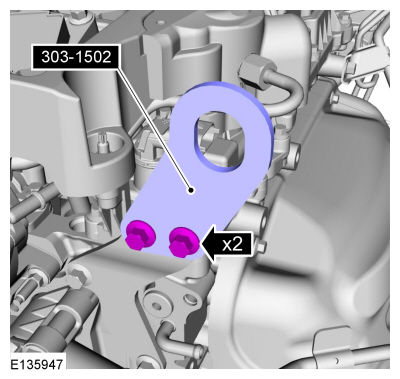

303-1502

Lifting Device Engine

TKIT-2012A-FL

TKIT-2012A-ROW |

|

303-409

(T92C-6700-CH)

Remover, Crankshaft Seal

TKIT-1992-FH/FMH/FLMH

TKIT-1993-LMH/MH |

|

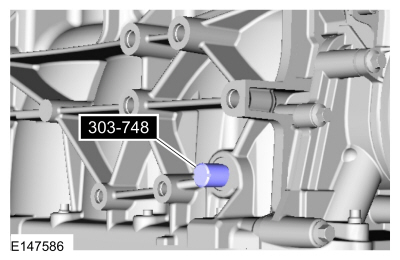

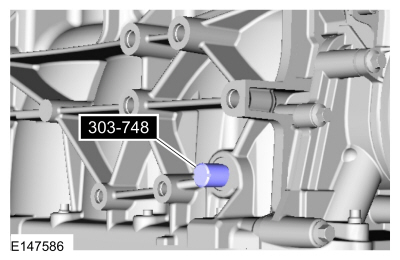

303-748

Locking Tool, Crankshaft

TKIT-2010B-FLM

TKIT-2010B-ROW |

|

307-005

(T59L-100-B)

Slide Hammer |

|

308-375

Remover, Input Shaft Seal

TKIT-2005U-M

TKIT-1999-F/FLM/LT |

|

310-206

Remover, Fuel Injector

TKIT-2009A-FLM |

| Hot Air Gun |

| Hose Clamp Remover/Installer |

Materials

| Name |

Specification |

Motorcraft® Metal Brake Parts Cleaner

PM-4-A, PM-4-B, APM-4-C |

-

|

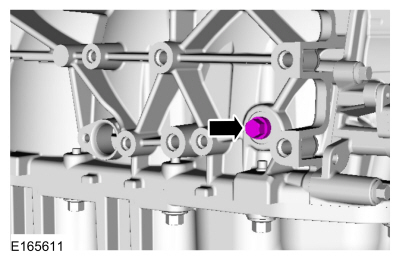

NOTICE:

Do not loosen or remove the crankshaft pulley bolt without first

installing the special tools. The crankshaft pulley and the crankshaft

timing sprocket are not keyed to the crankshaft. Before any repair

requiring loosening or removal of the crankshaft pulley bolt, the

crankshaft and camshafts must be locked in place by the special service

tools, otherwise severe engine damage can occur.

NOTICE:

During engine repair procedures, cleanliness is extremely

important. Any foreign material, including any material created while

cleaning gasket surfaces that enters the oil passages, coolant passages

or the oil pan, can cause engine failure.

NOTE:

Refer to exploded views in Description and Operation.

-

NOTICE:

Do not breathe dust or use compressed air to blow dust

from storage containers or friction components. Remove dust using

government-approved techniques. Friction component dust may be a cancer

and lung disease hazard. Exposure to potentially hazardous components

may occur if dusts are created during repair of friction components,

such as brake pads and clutch discs. Exposure may also cause irritation

to skin, eyes and respiratory tract, and may cause allergic reactions

and/or may lead to other chronic health effects. If irritation persists,

seek medical attention or advice. Failure to follow these instructions

may result in serious personal injury.

Loosen the 6 clutch pressure plate-to-flywheel bolts evenly, by 2 turns at a time.

-

-

-

Remove Special Service Tool: 300-OTC1819E

2,200# Floor Crane, Fold Away.

-

Remove Special Service Tool: 303-1502

Lifting Device Engine.

-

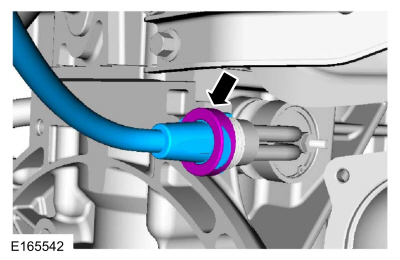

If equipped with block heater.

-

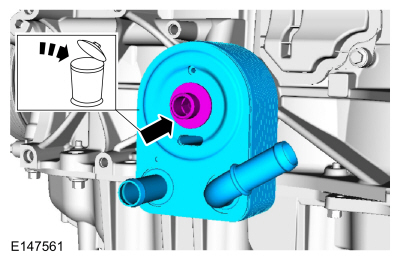

NOTE:

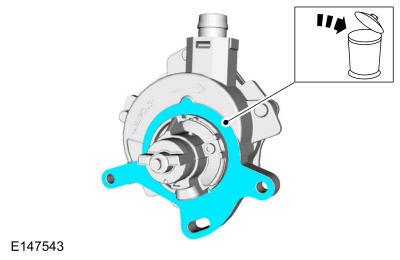

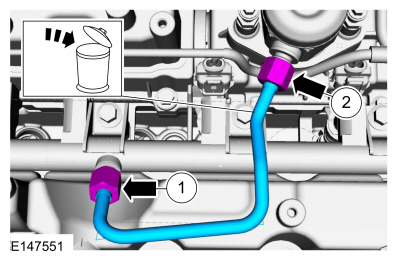

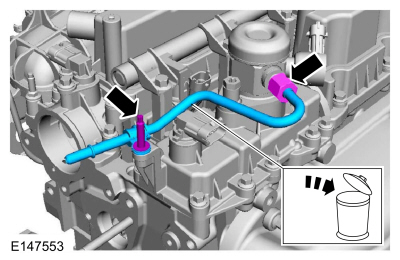

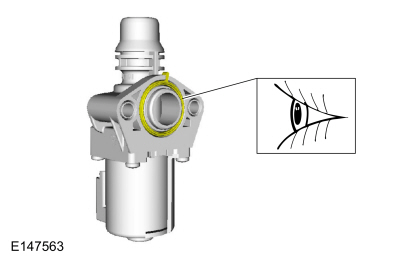

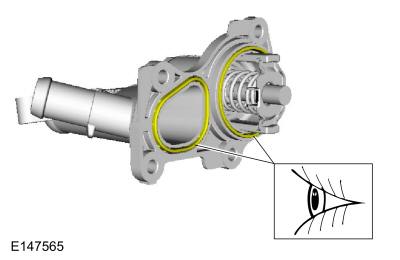

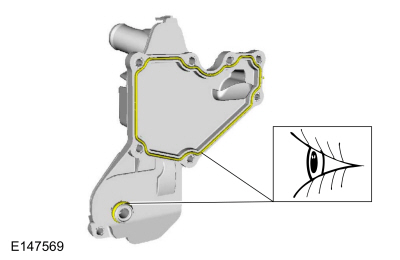

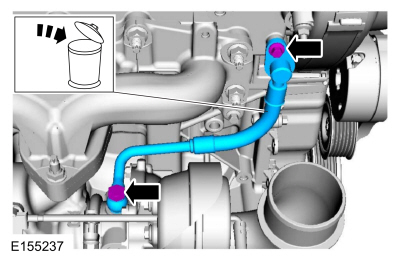

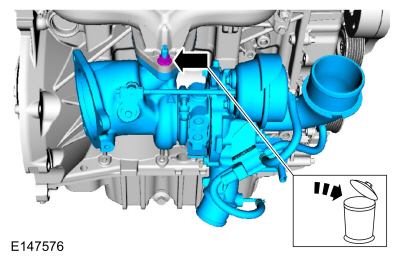

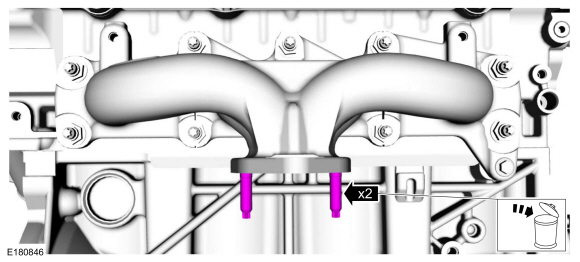

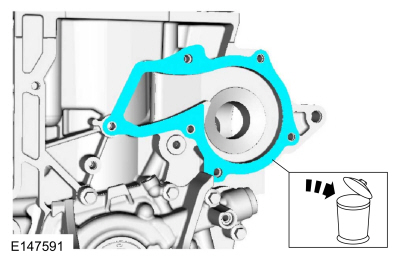

Discard the O-ring seals and gasket seals.

-

-

If equipped.

-

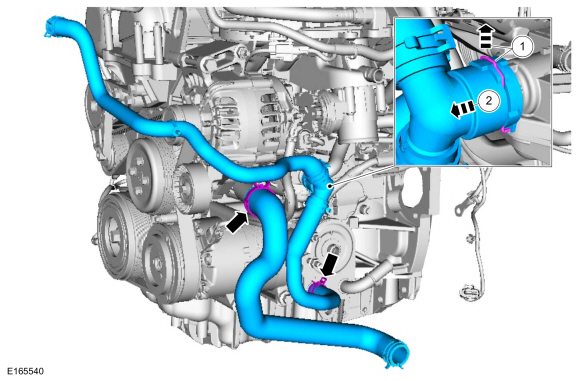

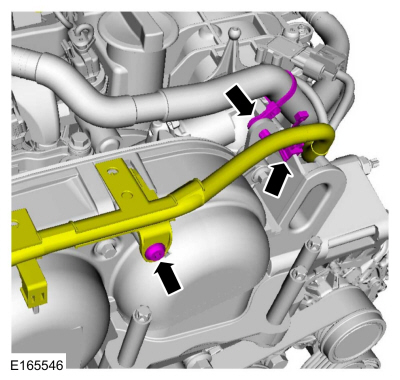

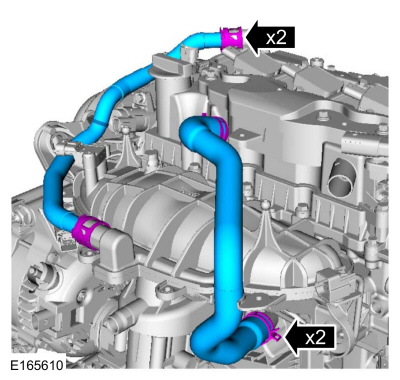

Use the General Equipment: Hose Clamp Remover/Installer

-

Use the General Equipment: Hose Clamp Remover/Installer

-

Use the General Equipment: Hose Clamp Remover/Installer

-

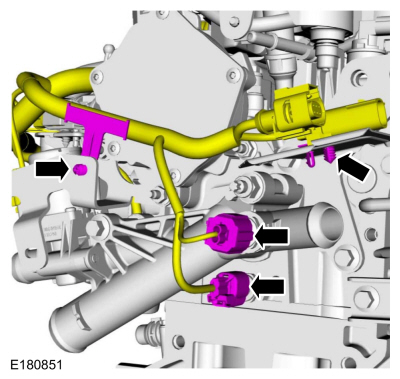

Use the General Equipment: Hose Clamp Remover/Installer

-

Use the General Equipment: Hose Clamp Remover/Installer

-

Use the General Equipment: Hose Clamp Remover/Installer

-

-

-

-

-

-

-

-

-

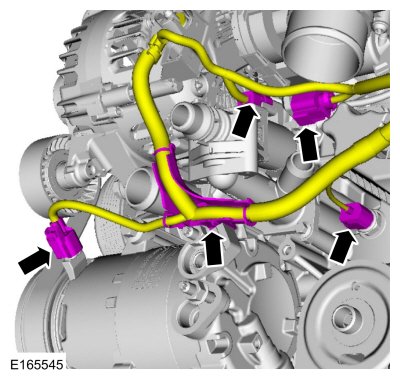

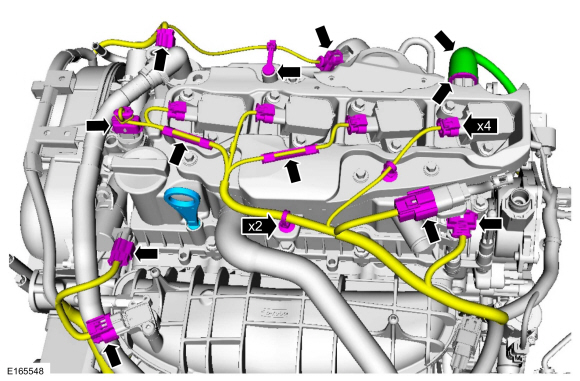

Use the General Equipment: Hose Clamp Remover/Installer

-

-

-

-

-

-

-

-

-

-

-

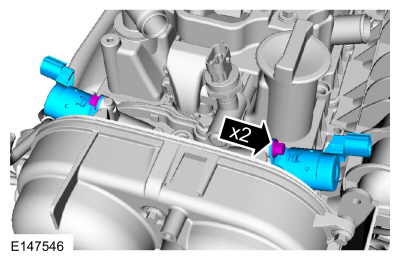

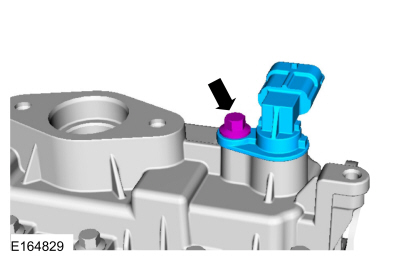

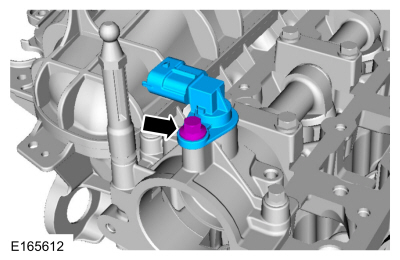

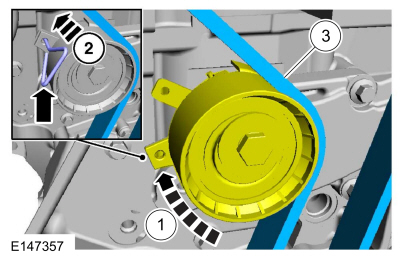

NOTE:

Note the position of the component before removal.

-

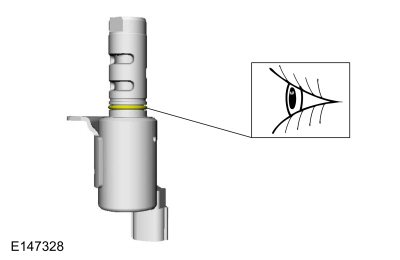

NOTE:

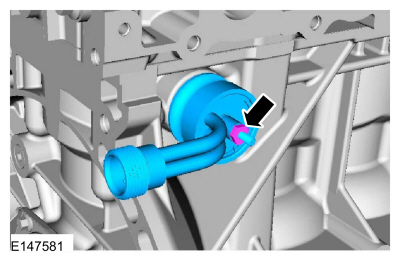

The O-ring seals are to be reused unless damaged.

-

NOTICE:

When removing or installing the fuel injection pump

noise insulator, spreading the openings will reduce the risk of damage.

-

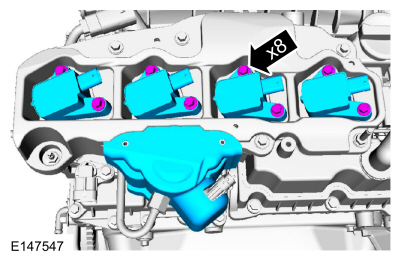

NOTE:

Replace any damaged coil-on-plug assemblies.

-

-

-

-

-

-

-

-

-

-

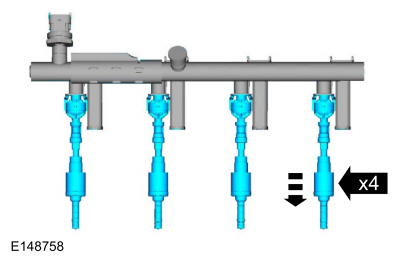

NOTICE:

Pull out the fuel rails in the direction of the fuel injector axis or damage may occur to the fuel injectors.

NOTE:

Use compressed air and remove any dirt or foreign

material from the cylinder head, block and general surrounding area of

the fuel rail and injectors.

NOTE:

When removing the fuel rails, the fuel injectors may

remain in the fuel rails but normally remain in the cylinder heads and

require the use of a Fuel Injector Remover tool to extract.

-

NOTE:

Take extra care when handling the components.

Remove any of the fuel injectors that remained in the fuel rail.

-

-

NOTE:

Remove the fuel injectors that remained in the head.

-

Use Special Service Tool: 307-005

(T59L-100-B)

Slide Hammer.

-

Use Special Service Tool: 310-206

Remover, Fuel Injector.

-

NOTICE:

Do not set the valve cover sealing surface face down on a

bench as the check valve and splitter leg is susceptible to breakage.

-

-

-

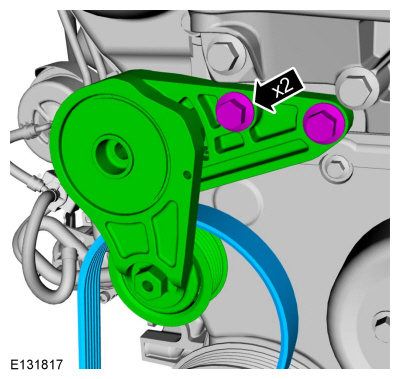

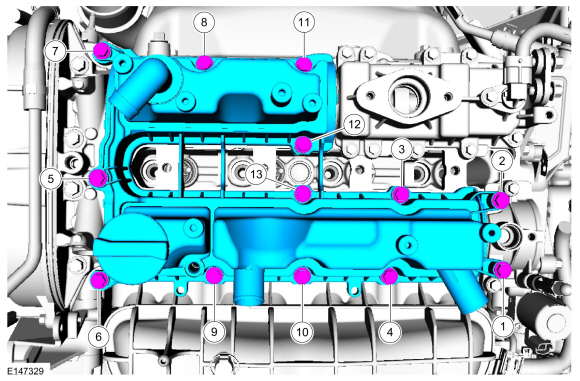

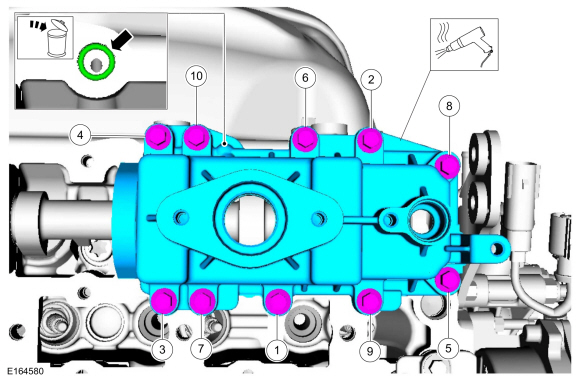

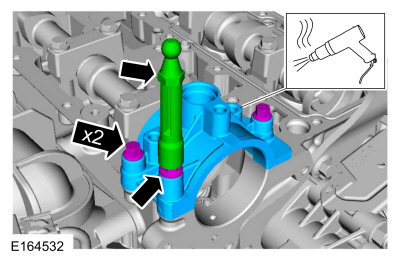

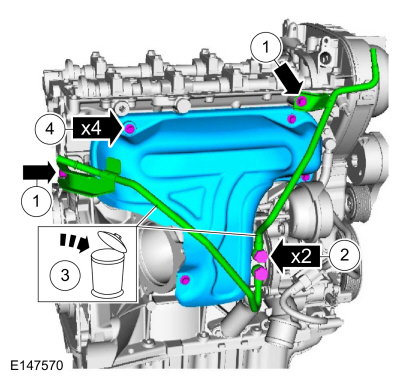

NOTICE:

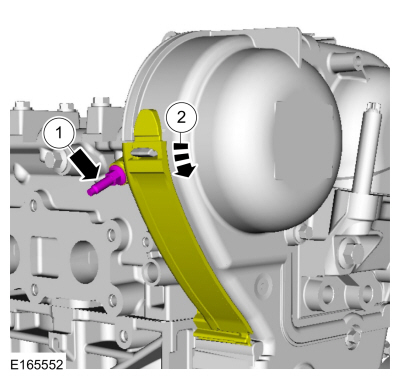

Use a heat gun to soften the flange sealant, this will

aid in the removal of the fuel pump mounting bracket. Failure to follow

these directions may result in damage to the fuel pump mounting bracket.

Use the General Equipment: Hot Air Gun

-

-

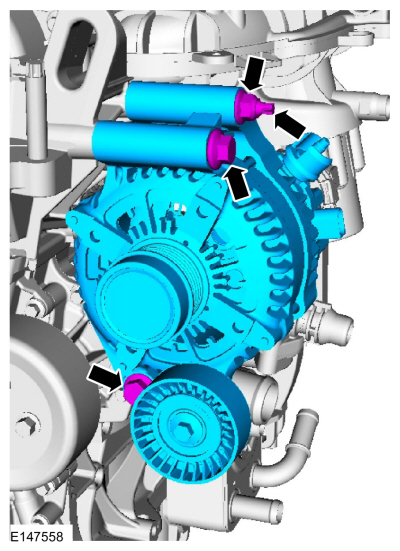

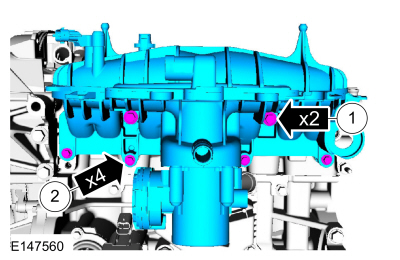

NOTICE:

Use a heat gun to soften the flange sealant, this will

aid in the removal of the brake vacuum pump mounting bracket. Failure to

follow these directions may result in damage to the brake vacuum pump

mounting bracket.

Use the General Equipment: Hot Air Gun

-

NOTE:

Note the different lengths of the bolts.

-

-

-

-

-

-

-

-

NOTE:

Note the position for installation.

-

-

-

-

-

-

-

-

-

-

-

-

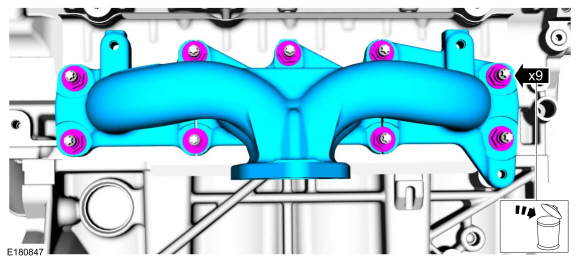

Refer to: Exhaust Manifold Cleaning and Inspection (303-00 Engine System - General Information, General Procedures).

-

-

NOTE:

Note the position for installation.

If equipped with block heater.

-

-

-

NOTE:

Note the different lengths of the bolts.

-

NOTE:

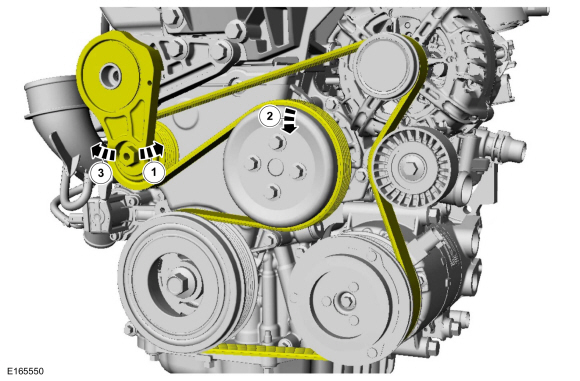

Only rotate the crankshaft in a clockwise direction.

11 o'clock position.

-

-

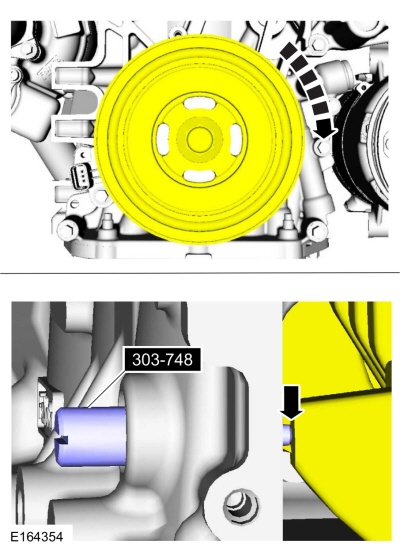

NOTE:

The Crankshaft TDC Timing Pin will contact the crankshaft and prevent

it from turning past TDC . However, the crankshaft can still be rotated

in the counterclockwise direction. The crankshaft must remain at the TDC

position during the crankshaft pulley removal and installation.

Install Special Service Tool: 303-748

Locking Tool, Crankshaft.

-

NOTE:

Only rotate the crankshaft clockwise direction.

Rotate the crankshaft slowly clockwise until the crankshaft balance

weight is up against the TDC Timing Peg. The engine is now at TDC .

-

-

-

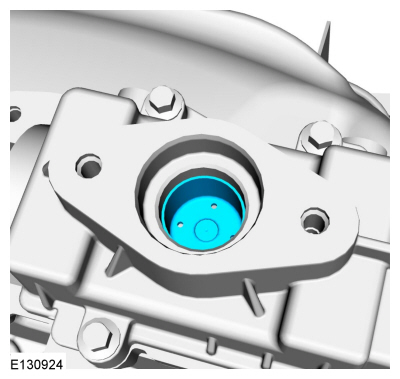

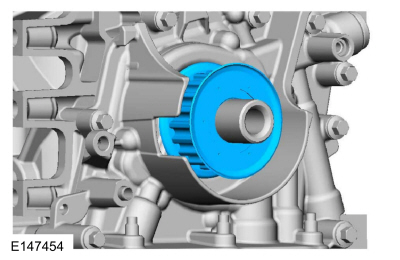

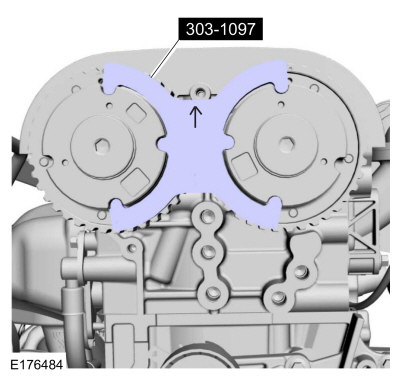

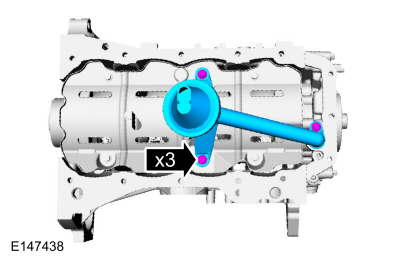

NOTE:

The timing mark of each VCT unit must be at the 12 o'clock position.

NOTE:

It may necessary to rotate the camshafts slightly to install the special tool.

Install Special Service Tool: 303-1097

Locking Tool, Variable Camshaft Timing Oil Control Unit.

-

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

Install a holding pin.

-

-

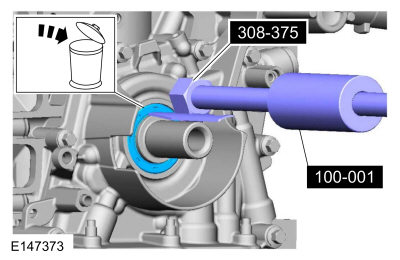

Use Special Service Tool: 308-375

Remover, Input Shaft Seal.

, 100-001

(T50T-100-A)

Slide Hammer.

-

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

-

Torque:

89 lb.in (10 Nm)

-

-

Remove Special Service Tool: 303-1097

Locking Tool, Variable Camshaft Timing Oil Control Unit.

-

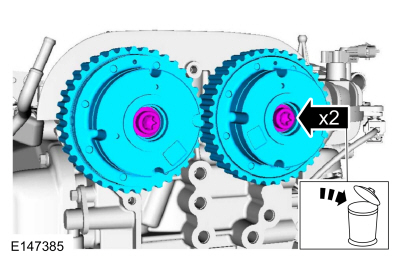

NOTE:

Use an open-ended wrench to hold the camshafts by the hexagon to prevent the camshafts from turning.

-

NOTE:

Use an open-ended wrench to hold the camshafts by the hexagon to prevent the camshafts from turning.

-

Use Special Service Tool: 303-409

(T92C-6700-CH)

Remover, Crankshaft Seal.

-

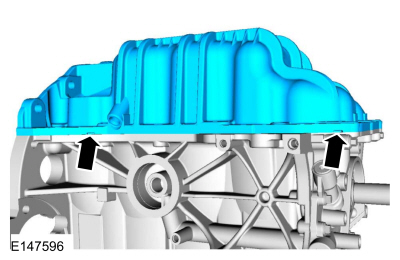

NOTICE:

Use a heat gun to soften the flange sealant, this will

aid in the removal of the camshaft mega cap. Failure to follow these

directions may result in damage to the camshaft mega cap.

NOTICE:

Do not pry on camshafts when removing or damage to the camshafts may occur.

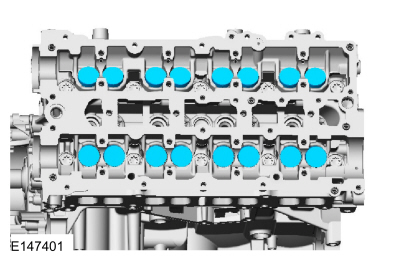

NOTE:

Note the location and orientation of each camshaft

bearing cap and the position of the camshaft lobes on the No. 1 cylinder

for installation reference.

Use the General Equipment: Hot Air Gun

-

-

NOTE:

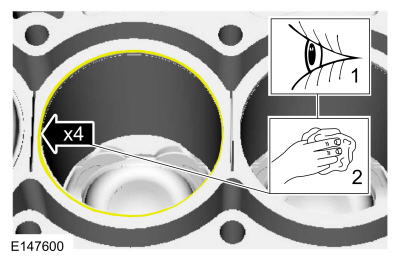

If the camshafts and valve tappets are to be reused,

mark the location of the valve tappets to make sure they are assembled

in their original positions.

NOTE:

The number on the valve tappets only reflects the digits

that follow the decimal. For example, a tappet with the number 0.650

has the thickness of 3.650 mm.

-

Install new components as necessary.

-

NOTE:

Make sure that the cylinder head is at ambient air temperature before removing the cylinder head bolts.

-

-

-

Refer to: Cylinder Head Distortion (303-00 Engine System - General Information, General Procedures).

Refer to: Cylinder Block Distortion (303-00 Engine System - General Information, General Procedures).

-

Remove Special Service Tool: 303-748

Locking Tool, Crankshaft.

-

-

Pry pads.

-

-

NOTE:

The O-ring seal is to be reused unless damaged.

-

-

-

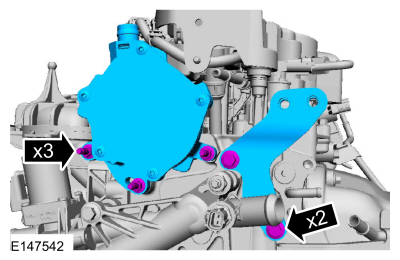

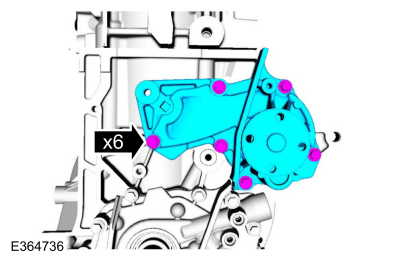

NOTE:

Note the position of the 3 different lengths of the bolts for installation.

-

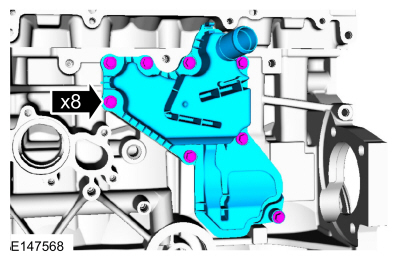

Remove the two M6 x 55 mm bolts.

-

Remove the three M6 x 35 mm bolts.

-

Remove the three M6 x 25 mm bolts and remove the oil pump.

-

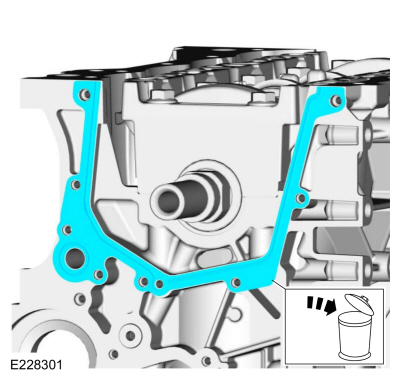

Remove and discard the oil pump gasket.

-

-

Clean the bolt holes for the oil pump with Motorcraft® Metal Brake Parts Cleaner to remove all residual oil.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B, APM-4-C

-

Use compressed air to remove any brake clean or oil in the oil pump bolt holes.

-

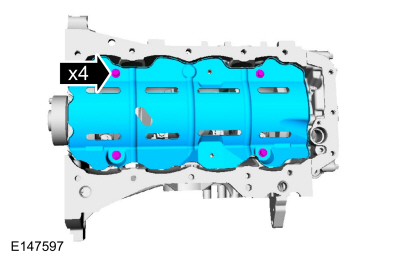

Clean the specified component with a abrasive pad.

-

NOTE:

The connecting rod cap bolts are a torque-to-yield

design. The original connecting rod cap bolts will be used when

measuring the connecting rod large end bore during assembly. The

connecting rod cap bolts will be discarded after measurement.

NOTE:

Clearly mark the connecting rods, connecting rod caps

and connecting rod bearings in numerical order for correct orientation

for reassembly.

-

NOTE:

Do not scratch the cylinder walls or crankshaft journals with the connecting rod.

Using a connecting rod installer, repeat until all the piston/rod assemblies are removed from the engine block.

-

NOTE:

Mark the position of the parts, so they can be installed in their original positions.

-

Refer to: Piston Inspection (303-00 Engine System - General Information, General Procedures).

-

NOTE:

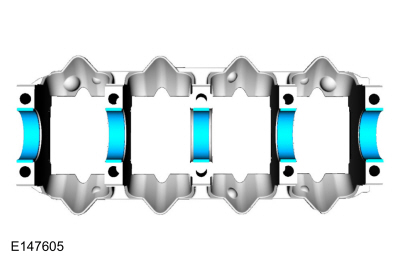

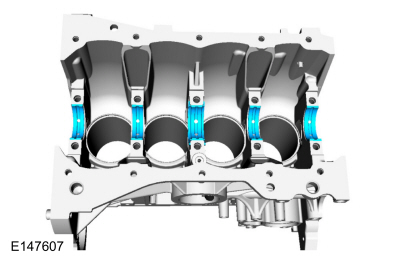

The main bearing beam has 2 arrows pointing towards the front of engine for correct orientation for reassembly.

-

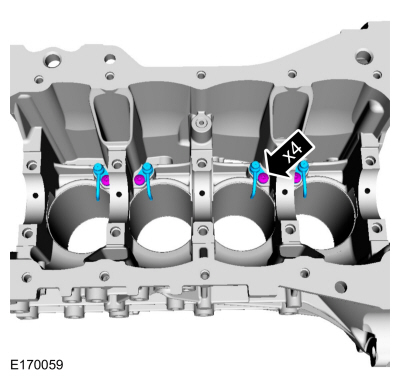

NOTE:

If the main bearings are being reused, mark them in order for correct orientation and reassembly.

-

-

NOTE:

If the main bearings are being reused, mark them in order for correct orientation and reassembly.

NOTE:

The center bulkhead has the thrust bearing.

-

Special Tool(s) /

General Equipment

303-1249Valve Spring CompressorTKIT-2006UF-FLMTKIT-2006UF-ROW

303-300

(T87C-6565-A)

Set, Valve Spring CompressorTKIT-1988-FESTIVAT88C-1000-STTKIT-1988-TRACERTKIT-2009TC-F

303-350

(T89P-6565-A)

Compressor, Valve SpringTKIT-1990-LMHTKIT-1989-FTKIT-1989-FMTKIT-1989-FLM

303-472

(T94P-6565-AH)

Adapter, Valve Sp..

Other information:

U0155:00

Normal Operation and Fault Conditions

The RCM uses information contained in messages from the IPC sent on the HS-CAN .

DTC Fault Trigger Conditions

DTC

Description

Fault Trigger Conditions

U0155:00

Lost Communication with Instrument Panel Cluster (IPC) ..

Repair

NOTE:

If the seatbelt webbing does not extract from the seatbelt

retractor from the stowed position, this may be due to a normal

condition which happens when the seatbelt retracts at a high rate of

speed. Follow these steps to release the seatbelt.

Front row seatbelt retractor

NOTE:

Typical front outboard seatbelt retractor shown, other configurations similar.

N..

Categories

Special Tool(s) /

General Equipment

Flat Headed Screw Driver

Transmission Jack

Vehicle/Axle Stands

Removal

NOTICE:

Suspension fasteners are critical parts that affect

performance of vital components and systems. Failure of these fasteners

may result in major service expense. Use the same or equivalent parts if

replacement is necessary. Do not use a replacement part of lesser

quality or substitute design. Tighten fasteners as specified.

Remove the floor console.

Refer to: Floor Console (501-12 Instrum

read more

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

WARNING:

The timing belt tensioner spring is under load. Extra

care must be taken at all times when handling the tensioner. Failure to

follow this instruction may result in personal injury.

Engine. Removal

Engine. Removal Cylinder Head. Disassembly and Assembly of Subassemblies

Cylinder Head. Disassembly and Assembly of Subassemblies