Ford Fiesta: Side Panel Sheet Metal Repairs / B-Pillar Outer Panel. Removal and Installation

Ford Fiesta 2014 - 2019 Service Manual / Body and Paint / Side Panel Sheet Metal Repairs / B-Pillar Outer Panel. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Hot Air Gun | |

| Air Body Saw | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Refer to: Body Repair Health and Safety and General Precautions (100-00 General Information, Description and Operation). WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

-

Rough straighten to restore the vehicle to pre-accident dimensions.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

Refer to: Headliner - 4-Door (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Headliner - 5-Door (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

-

Remove the rear door hinges and the front door striker.

-

Remove the roof ditch trim.

|

-

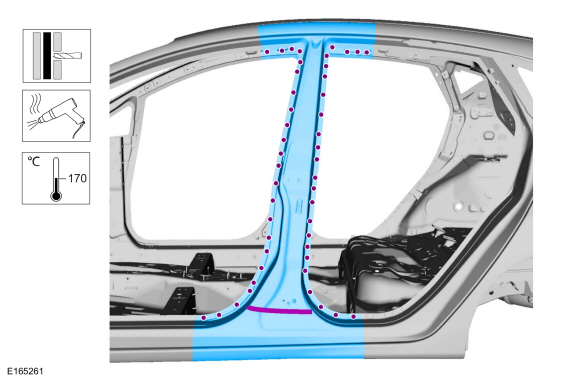

Carefully measure and cut the outer B-pillar as indicated.

Use the General Equipment: Air Body Saw

|

-

Drill out the spot welds from the lower portion of the B-pillar panel.

Use the General Equipment: Spot Weld Drill Bit

|

-

Break the adhesive bond, drill out the spot welds and remove the B-pillar panel.

Use the General Equipment: Spot Weld Drill Bit

Use the General Equipment: Hot Air Gun

|

Installation

-

Carefully measure and cut the replacement panel to fit repair area.

Use the General Equipment: Air Body Saw

|

-

Apply adhesive as indicated.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

NOTE: The B-pillar to roof joint is allowed to overlap the roof flange.

-

Install and clamp the new B-pillar outer panel.

Use the General Equipment: Locking Pliers

-

Spot and seam weld the B-pillar outer panel.

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Resistance Spotwelding Equipment

-

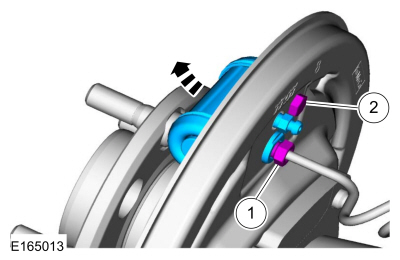

Install and clamp the new B-pillar outer panel.

|

-

Spot weld the lower portion of the B-pillar panel.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Metal finish the repair area using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

-

NOTE: Seam seal the B-pillar to roof joint after primer application and before final paint application to prevent water and wind leaks.

Refinish using a Ford approved paint system.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the roof ditch trim.

|

-

Install the rear door hinges and the front door striker.

-

Install the following items:

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

Refer to: Headliner - 4-Door (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Headliner - 5-Door (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

-

Align the rear door.

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

B-Pillar and Reinforcement. Removal and Installation

B-Pillar and Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

The B-pillar inner reinforcement is constructed of boron

steel and cannot be sectioned...

Front Door Skin Panel. Removal and Installation

Front Door Skin Panel. Removal and Installation

Special Tool(s) /

General Equipment

Grinder

Hot Air Gun

Knife

MIG/MAG Welding Equipment

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Flexible Foam Repair3M™ 08463, LORD Fuso..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Headlamps. Diagnosis and Testing

DTC Chart: BCM Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). BCM DTC Chart DTC Description Action B1007:92 High-Beam Head..

Ford Fiesta 2014 - 2019 Service Manual: Rear Seatbelt Buckle. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the rear seat cushion. Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation). Remove the bolt and the rear seatbelt buckles. Torque: 35 lb.ft (48 Nm) Installation NOTE: During installation, m..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Front Suspension

- Clutch - 6-Speed Manual Transmission – B6

- Service Information

- Engine Component View. Description and Operation

- Manual Transmission - 6-Speed Manual Transmission – B6

Brake Backing Plate. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the brake shoes.Refer to: Brake Shoes (206-02 Drum Brake, Removal and Installation).

Disconnect the brake tube fitting.

Torque: 159 lb.in (18 Nm) Remove the bolt and wheel cylinder.

Torque: 106 lb.in (12 Nm)

Disconnect the brake shoe lever fitting and re

Disconnect the brake shoe lever fitting and re

Copyright © 2025 www.fofiesta7.com