Ford Fiesta: Starting System - 1.6L EcoBoost (132kW/180PS) – Sigma / Starting System. Diagnosis and Testing

Inspection and Verification

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

-

Verify the customer concern by operating the starting system.

-

Before diagnosing or repairing the starting system inspect the following items:

- Check the battery for loose, damaged or corroded connections

- Check the generator for loose, damaged or corroded connections

- Fusible links

- Check engine and battery grounds for loose, damaged or corroded connections

- High current BJB for loose or corroded connections

- Wiring, terminals or connectors

-

Check the battery condition and state of charge.

REFER to: Battery (414-01 Battery, Mounting and Cables, Diagnosis and Testing).

-

Check for abnormal ignition-off current drain(s).

REFER to: Battery Drain Check (414-01 Battery, Mounting and Cables, General Procedures).

-

Remove the accessory drive belt.

REFER to: Accessory Drive Belt (303-05B Accessory Drive - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Verify the crankshaft and each of the components driven by the accessory drive belt rotate and are not seized or damaged.

-

If any aftermarket accessories have been added to the vehicle, make sure they are properly wired.

-

If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding.

DTC Charts

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

for information about these practices.

PCM DTC Chart

| DTC | Description | Action |

|---|---|---|

| PCM DTCs | PCM Diagnostic Trouble Codes (DTCs) not listed in this chart |

REFER to: Electronic Engine Controls (303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) – Sigma, Diagnosis and Testing). |

| P06E9 | Engine Starter Performance | If engine cranks, Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If the engine does not crank, GO to Pinpoint Test A |

| P0830 | Clutch Pedal "A" Circuit | GO to Pinpoint Test A |

| P0833 | Clutch Pedal "B" Circuit |

REFER to: Cruise Control (419-03 Cruise Control, Diagnosis and Testing). |

| P162F | Starter Motor Disabled - Engine Crank Time Too Long | Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. |

BCM DTC Chart

| DTC | Description | Action |

|---|---|---|

| BCM DTCs | BCM Diagnostic Trouble Codes (DTCs) not listed in this chart |

REFER to: Body Control Module (BCM) (419-10 Multifunction Electronic Modules, Diagnosis and Testing). |

| B10E5:11 | PCM Wake-up Signal: Circuit Short to Ground | GO to Pinpoint Test C |

RFA DTC Chart

| DTC | Description | Action |

|---|---|---|

| RFA DTCs | All RFA Diagnostic Trouble Codes (DTCs). |

REFER to: Remote Function Actuator (RFA) Module (419-10 Multifunction Electronic Modules, Diagnosis and Testing). |

Symptom Chart(s)

Symptom Chart: Starting System

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

for information about these practices.

Symptom Chart

| Condition | Possible Sources | Actions |

|---|---|---|

| The engine does not crank | Refer to the Pinpoint Test. | GO to Pinpoint Test A |

| The engine cranks slowly | Refer to the Pinpoint Test. | CARRY OUT the starter system component test. Refer to Starter Motor - Positive Circuit Test in this section. |

| The engine cranks but will not start | Ignition fault | Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. |

| Unusual starter noise | Refer to the Pinpoint Test. | GO to Pinpoint Test B |

| The starter spins but the engine does not crank | Starter motor | INSPECT the starter motor mounting and engagement. REPAIR as necessary. |

| Damaged flexplate | INSPECT the flexplate for damaged, missing or worn teeth. REPAIR as necessary. | |

| The starter does not disengage from the flexplate |

|

REMOVE the starter relay. If the engine stops cranking, INSTALL a new relay. If the engine continues to crank, REPAIR circuit CDC26 (GY/OG) for a short to voltage. |

Pinpoint Tests

Engine Does Not Crank

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Refer to Wiring Diagrams Cell 90 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Starting System - System Operation and Component

Description (303-06B Starting System - 1.6L EcoBoost (132kW/180PS) –

Sigma, Description and Operation).

DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| P06E9 | Engine Starter Performance | Sets when no engine rotation is detected during crank event. |

| P0830 | Clutch Pedal "A" Circuit | Sets when the PCM receives vehicle speed input, indicating vehicle movement and does not detect the switching input from the clutch pedal position switch. |

Possible Sources

- Battery

- Battery cables

- Starter motor

- BJB starter relay

Visual Inspection and Diagnostic Pre-checks

- Inspect high current BJB connections.

- Verify the BJB fuse 10 (30A).

- Verify the High Current BJB MEGA 1 fuse (450A).

- Inspect the CPP switch.

- Inspect the Passive Key.

PINPOINT TEST A: ENGINE DOES NOT CRANK

| A1 PERFORM INSPECTION AND VERIFICATION | |||||||||||||

|

NOTE: Make sure battery voltage is greater than 12.2 volts prior to and during this pinpoint test. NOTE: If it is necessary to leave the battery charger connected during testing, do not leave it on its highest or boost setting. The highest settings can exceed 16 volts, resulting in false test results and setting of Diagnostic Trouble Codes (DTCs).

Was an obvious cause for an observed or reported concern found?

|

|||||||||||||

| A2 CHECK FOR NO KEY DETECTED MESSAGE IN THE MESSAGE CENTER | |||||||||||||

Is No Key Detected displayed?

|

|||||||||||||

| A3 CHECK THE IPC (INSTRUMENT PANEL CLUSTER) OPERATION | |||||||||||||

Do some indicators in the IPC illuminate?

|

|||||||||||||

| A4 CHECK FOR COMMUNICATION WITH THE SCAN TOOL | |||||||||||||

Does the BCM , IPC and RFA module pass the Network Test?

|

|||||||||||||

| A5 RETRIEVE DTCS | |||||||||||||

Were Diagnostic Trouble Codes (DTCs) retrieved on-demand during self-test?

|

|||||||||||||

| A6 CHECK THE PCM (POWERTRAIN CONTROL MODULE) CLUTCH PEDAL AT OR NEAR BOTTOM OF TRAVEL (CPP_BOT) PID (PARAMETER IDENTIFICATION) | |||||||||||||

Does the PID change from NO to YES when the clutch pedal is fully applied?

|

|||||||||||||

| A7 CHECK THE PCM (POWERTRAIN CONTROL MODULE) ENGINE CRANKING (ENG_CRANK) PID (PARAMETER IDENTIFICATION) | |||||||||||||

Does the PID change from Inactive to Active?

|

|||||||||||||

| A8 CHECK THE STARTER RELAY CONTROL OPERATION | |||||||||||||

|

NOTICE: The following step uses a test light to simulate normal circuit loads. Use only the test light recommended in the Special Tools table at the beginning of this section. To avoid connector terminal damage, use the Flex Probe Kit for the test light probe connection to the vehicle. Do not use the test light probe directly on any connector.

Does the test light illuminate when the ignition switch - push button start and brake pedal are pressed?

|

|||||||||||||

| A9 CHECK THE VOLTAGE TO THE STARTER RELAY | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A10 CHECK THE STARTER MOTOR OPERATION AT THE STARTER RELAY | |||||||||||||

Did the starter engage and the engine crank?

|

|||||||||||||

| A11 CHECK THE BATTERY GROUND CABLE | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A12 CHECK THE STARTER MOTOR GROUND | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A13 CHECK THE VOLTAGE TO THE STARTER MOTOR | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A14 CHECK THE STARTER MOTOR FOR CORRECT OPERATION | |||||||||||||

Was an obvious cause found?

|

|||||||||||||

| A15 CHECK FOR START INPUT AT THE STARTER | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A16 CHECK THE PCM (POWERTRAIN CONTROL MODULE) STARTER RELAY CIRCUITS FOR A SHORT TO GROUND | |||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||

| A17 CHECK THE PCM (POWERTRAIN CONTROL MODULE) STARTER RELAY CIRCUITS FOR AN OPEN | |||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||

| A18 CHECK THE CRANK DETECT CIRCUIT FOR VOLTAGE AT THE PCM (POWERTRAIN CONTROL MODULE) | |||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||

| A19 CHECK THE CPP (CLUTCH PEDAL POSITION) SWITCH | |||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||

| A20 CHECK THE CPP (CLUTCH PEDAL POSITION) GROUND CIRCUIT FOR AN OPEN | |||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||

| A21 CHECK THE CPP (CLUTCH PEDAL POSITION) SWITCH CIRCUIT FOR AN OPEN | |||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||

| A22 CHECK THE CLUTCH BOTTOM TRAVEL CIRCUIT FOR A SHORT TO GROUND | |||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||

| A23 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | |||||||||||||

Is the concern still present?

|

Unusual Starter Noise

Normal Operation and Fault Conditions

Correct starter operation relies on correct mounting of the starter to the engine, alignment of the starter ring gear to the flexplate and correct functioning of the starter assembly (internal gears, bearings).

Possible Sources

- Engine

- Starter motor

- Starter motor mounting

Visual Inspection and Diagnostic Pre-checks

- Inspect the starter motor.

- Inspect the starter motor mounting.

PINPOINT TEST B: UNUSUAL STARTER NOISE

| B1 CHECK THE STARTER MOUNTING | ||||

Is the starter motor mounted correctly?

|

||||

| B2 CHECK FOR ENGINE NOISE | ||||

Is the noise due to the starter engagement?

|

B10E5:11

Refer to Wiring Diagrams Cell 23 for schematic and connector information.

Normal Operation and Fault Conditions

The wake-up control circuit wakes up the PCM prior to engine cranking. The PCM needs to wake up prior to a crank request so it has time to go through its initialization. The wake-up control circuit is controlled by the BCM . The BCM activates the wake-up control circuit when: the driver door is opened. a key is inserted into the ignition. or when the ignition is in the ON or START position.

DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B10E5:11 | PCM Wake-up Signal: Circuit Short to Ground | Set by the BCM when a short to ground is detected on the wake-up control circuit. |

Possible Sources

- BCM

- PCM

- Wiring, terminals or connectors

PINPOINT TEST C: B10E5:11

| C1 CHECK THE PCM (POWERTRAIN CONTROL MODULE) FOR A SHORT TO GROUND | ||||||||||

Is BCM DTC B10E5:11 present?

|

||||||||||

| C2 CHECK THE PCM (POWERTRAIN CONTROL MODULE) WAKE-UP SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| C3 CHECK THE PCM (POWERTRAIN CONTROL MODULE) WAKE-UP SIGNAL CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| C4 CHECK THE PCM (POWERTRAIN CONTROL MODULE) WAKE-UP SIGNAL CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| C5 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| C6 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

Component Test(s)

Starter Motor - Positive Circuit Test

NOTE: Always make the digital multimeter connection at the component terminal rather than at the wiring end of the connector. Making a connection at the wiring end of the connector could result in false readings because the meter will not pick up a high resistance between the wiring connector and component.

-

Make sure the battery is fully charged.

REFER to: Battery Charging (414-01 Battery, Mounting and Cables, General Procedures).

-

Perform a battery drain test.

REFER to: Battery Drain Check (414-01 Battery, Mounting and Cables, General Procedures).

-

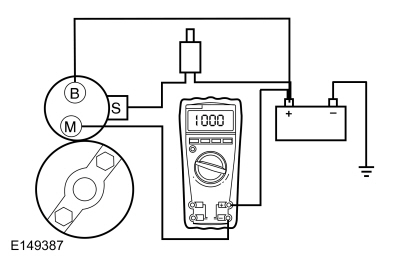

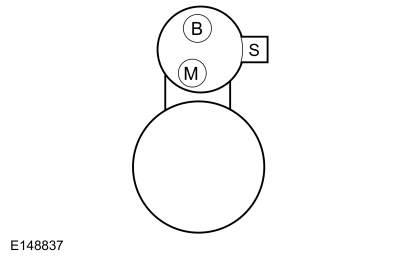

Connect a remote starter switch between starter solenoid “S” terminal and the battery positive terminal.

-

Connect the digital multimeter positive lead to the

battery positive post. Connect the negative lead to the starter solenoid

"M" terminal.

-

Place gear select lever in Park or Neutral.

-

Engage the remote starter switch. Read and record the voltage. The voltage reading should be 0.5 volt or less.

-

If the voltage reading is 0.5 volt or less, perform Starter Motor - Ground Circuit Test in this section.

-

A voltage reading greater than 0.5 volt, this is an

indication of excessive resistance in the connections, the positive

battery cable or in the starter solenoid. Remove the cables from the

solenoid "B", "S" and "M" terminals. Clean the cables and connections

and reinstall the cables to the correct terminals. Repeat Steps 3

through 6.

-

If the voltage reading is still greater than 0.5 volt

when checked at the "M" terminal, move the digital multimeter negative

lead to the starter solenoid “B” terminal and repeat Step 5.

-

If the voltage reading at the "B" terminal is lower than

0.5 volt, the concern is in the connections at the starter solenoid or

in the solenoid contacts. Install a new starter motor.

REFER to: Starter Motor (303-06B Starting System - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

-

If the voltage reading taken at the solenoid "B"

terminal is greater than 0.5 volt after cleaning the cables and

connections at the solenoid, the concern is in the positive battery

cable connection or in the positive battery cable itself. Clean the

positive battery cable connections. If this does not resolve the

concern, install a new positive battery cable.

Starter Motor - Ground Circuit Test

A slow cranking condition can be caused by resistance in the ground or return portion of the cranking circuit. This procedure checks the voltage drop in the ground circuit.

-

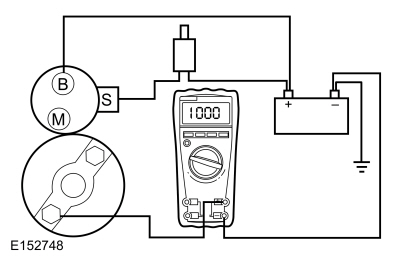

Connect a remote starter switch between starter solenoid "S" terminal and the battery positive terminal.

-

Connect the digital multimeter positive lead to the

starter motor housing (the connection must be clean and free of rust or

grease). Connect the negative lead to the negative battery terminal.

-

Place gear select lever in Park or Neutral.

-

Engage the remote starter switch and crank the engine.

Read and record the voltage reading. The reading should be 0.5 volt or

less.

-

If the voltage reading is greater than 0.5 volt, clean

the negative cable connections at the battery, the body ground

connections and the starter ground connections. Retest.

-

If the voltage reading is greater than 0.5 volt, install a new negative battery cable.

REFER to: Battery Monitoring Sensor (414-01 Battery, Mounting and Cables, Removal and Installation).

-

If the voltage reading is less than 0.5 volt and the engine still cranks slowly, install a new starter motor.

REFER to: Starter Motor (303-06B Starting System - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Starter Motor Drive Gear and Flywheel Ring Gear Inspection. General Procedures

Starter Motor Drive Gear and Flywheel Ring Gear Inspection. General Procedures

Activation

Refer to: Starter Motor (303-06B Starting System - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Check the wear patterns on the starter drive gear and

the flywheel or flexplate ring gear...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Front Door Tweeter Speaker. Removal and Installation

Removal Remove the front door handle. Refer to: Interior Front Door Handle (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). Release the tabs and remove the front door tweeter speaker. Disconnect the electrical connector...

Ford Fiesta 2014 - 2019 Service Manual: Turn Signal and Hazard Lamps. Diagnosis and Testing

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). DTC Chart: BCM BCM DTC Chart DTC Description Action B123A:11 Left Front..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Timing Belt. Removal and Installation

- General Information

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Manual Transmission, Clutch, Transfer Case and Power Transfer Unit

- Engine

Brake Drum. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

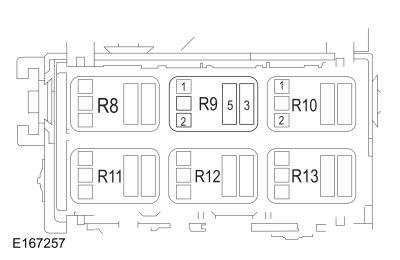

BJB starter relay pin 1

BJB starter relay pin 1

Starter motor case

Starter motor case