Ford Fiesta: Body Repairs - General Information / Plastic Repairs. Description and Operation

Plastic Components

The following illustration(s) are not all-inclusive of trim levels available. The actual trim level of the vehicle will determine the viability of carrying out a plastics repair. Typically components with moulded-in color or a textured finish are not considered repairable components.

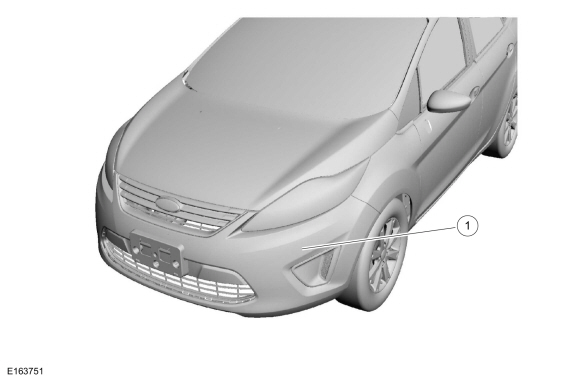

Front Exterior Plastic Components 4-Door

| Item | Description | Material |

| 1 | Front bumper cover | Thermoplastic olefin (TPO) |

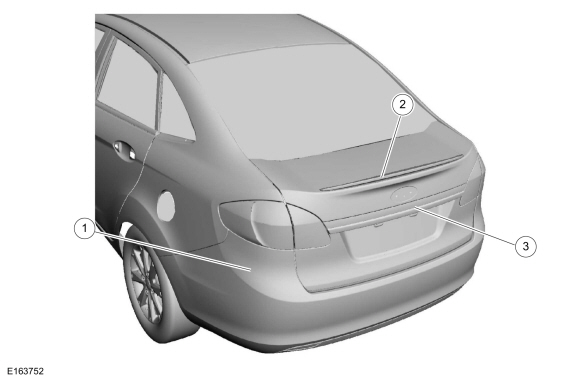

Rear Exterior Plastic Components 4-Door

| Item | Description | Material |

| 1 | Rear bumper cover | Thermoplastic olefin (TPO) |

| 2 | Rear spoiler | Acrylonitrile butadiene styrene (ABS) |

| 3 | Luggage compartment lid handle | Acrylonitrile butadiene styrene (ABS) |

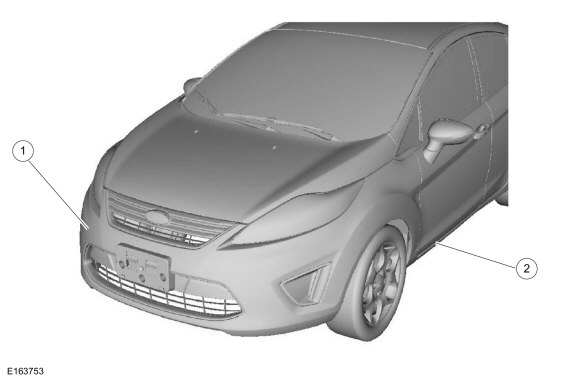

Front Exterior Plastic Components 5-Door

| Item | Description | Material |

| 1 | Front bumper cover | Thermoplastic olefin (TPO) |

| 2 | Rocker panel moulding | Thermoplastic olefin (TPO) |

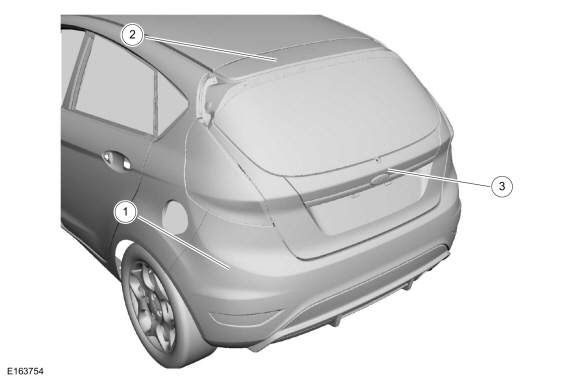

Rear Exterior Plastic Components 5-Door

| Item | Description | Material |

| 1 | Rear bumper cover | Thermoplastic olefin (TPO) |

| 2 | Rear spoiler | Acrylonitrile butadiene styrene (ABS) |

| 3 | Liftgate handle | Acrylonitrile butadiene styrene (ABS) |

Repair Considerations

Several considerations will determine viability of plastic repair procedure(s):

- Is the damage cosmetic or structural?

- Can the repair be carried out on the vehicle?

- Is the part readily available?

- Is component repair the most cost effective method?

- Will the repair provide for the fastest, highest quality repair?

Several types of plastic are in use for automotive application. However, all plastics will fall into 2 primary categories of thermoplastic or thermosetting plastic.

Thermosetting Plastic

Generally, thermosetting plastics are made with 2-part thermosetting resins. When mixed together, heat is generated, producing a cure that is irreversible. Because of this, thermosetting plastics will require the use of a 2-part adhesive for repair.

Sheet-Molded Composite (SMC):

- Sheet-Molded Composite (SMC) is a type of thermosetting plastic that uses glass fibers or nylon fibers in combination with thermosetting polyester resins. When fully cured, Sheet-Molded Composite (SMC) is strong and rigid.

- Sheet-Molded Composite (SMC) is similar to, but not identical to fiberglass. Ford Motor Company uses Sheet-Molded Composite (SMC) in components such as fenders, hoods and liftgates.

Thermoplastic Compounds

Thermoplastic compounds are manufactured by a process that is reversible. Thermoplastics can be remolded repeatedly by reheating. This characteristic of thermoplastics makes plastic welding a possible repair alternative. A repair of thermoplastic compounds is still possible through the use of a 2-part adhesive and filler repair materials and reinforcements as needed. Thermoplastics are widely used in interior trim components, wheel flares, body side cladding and bumper covers.

Polyolefin

Polyolefins fall into the family of thermoplastics with one unique characteristic: an oily or waxy feel to the material when sanded or ground. Polyolefin lends itself very well to remolding through the use of heat. Because of this, components made of this material lend themselves well to the possibility of plastic welding. Most adhesive repair materials and paint will not bond to the surface of a polyolefin unless an adhesion promoter specially formulated for plastic is first applied to the exposed raw surface. Otherwise, polyolefins are repaired like most other thermoplastics. Polyolefins are used in bumper covers, fan shrouds and wheel housings.

Proper

identification of the various types of plastic is necessary to select

the appropriate repair method(s) to carry out high quality plastic

repairs.

For additional information, refer to: Plastic Repairs (501-25 Body Repairs - General Information, General Procedures).

Sealer, Underbody Protection Material and Adhesives. Description and Operation

Sealer, Underbody Protection Material and Adhesives. Description and Operation

Adhesives

NOTE:

The following illustrations are examples of structural adhesive application and are not all inclusive.

The

correct adhesive bonding is essential to repairing the vehicle

correctly...

Noise, Vibration and Harshness. Description and Operation

Noise, Vibration and Harshness. Description and Operation

Sound Deadeners and Insulators

NOTICE:

Mastic material is made of a combustible material and should

be removed prior to carrying out welding procedures to the area...

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Fuel Tank Draining. General Procedures

Special Tool(s) / General Equipment 292-00004Fuel Tanker 100 GPM Draining NOTICE: Do not remove the hose clamp at the filler neck hose to fuel tank connection. The plastic tank is susceptible to damage with over torquing and or multiple re-torques...

Ford Fiesta 2014 - 2019 Service Manual: Engine. Installation

Special Tool(s) / General Equipment 205-461Protector, Differential Oil Seal (pair)TKIT-2000AP-FLM/LMTKIT-2002-F/FM 300-OTC1585AEPowertrain Lift 300-OTC1819E2,200# Floor Crane, Fold Away 303-1502Lifting Device EngineTKIT-2012A-FLTKIT-2012A-ROW 303-476 (T94P-9472-A) Socket, Exhaust Gas Oxygen SensorTKIT-1994-LM/MTKIT-1994-FTKIT-1994-FLM/FM ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine Cooling - 1.6L EcoBoost (132kW/180PS) – Sigma

- Manual Transmission - 6-Speed Manual Transmission – B6

- General Information

- Front Subframe. Removal and Installation

Brake Master Cylinder. Removal and Installation

Removal

NOTICE: If the fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water.

NOTE: Removal steps in this procedure may contain installation details.

All vehicles

Remove the battery tray.Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Disconnect the vacuum tube from the brake booster and detach the routing clip.